2NZ-FE ENGINE MECHANICAL ENGINE ASSEMBLY REMOVAL

CAUTION / NOTICE / HINT

- CAUTION:

-

The engine assembly with transaxle is very heavy. Be sure to follow the procedure described in the repair manual, or the engine lifter may suddenly drop.

PROCEDURE

1. PRECAUTION

1. PRECAUTION

- NOTICE:

-

After turning the ignition switch off, waiting time may be required before disconnecting the cable from the negative (-) battery terminal. Therefore, make sure to read the disconnecting the cable from the negative (-) battery terminal notices before proceeding with work.

-

Click hereGeneral>INTRODUCTION>REPAIR INSTRUCTION>PRECAUTION

2. DISCHARGE FUEL SYSTEM PRESSURE

2. DISCHARGE FUEL SYSTEM PRESSURE

3.ALIGN FRONT WHEELS FACING STRAIGHT AHEAD

3.ALIGN FRONT WHEELS FACING STRAIGHT AHEAD

4. SECURE STEERING WHEEL

4. SECURE STEERING WHEEL

5.DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

5.DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

- NOTICE:

-

When disconnecting the cable, some systems need to be initialized after the cable is reconnected.

-

Click hereGeneral>INTRODUCTION>REPAIR INSTRUCTION>INITIALIZATION

6.REMOVE FRONT WHEELS

6.REMOVE FRONT WHEELS

51442C

7.REMOVE ENGINE UNDER COVER LH

51442C

7.REMOVE ENGINE UNDER COVER LH

Remove the 2 bolts, 4 screws, 3 clips and engine under cover LH.

51441C

8.REMOVE ENGINE UNDER COVER RH

51441C

8.REMOVE ENGINE UNDER COVER RH

Remove the 3 bolts, 4 screws, 3 clips and engine under cover RH.

9.DRAIN ENGINE COOLANT

9.DRAIN ENGINE COOLANT

10.DRAIN ENGINE OIL

10.DRAIN ENGINE OIL

11.DRAIN MANUAL TRANSAXLE OIL (for Manual Transaxle)

11.DRAIN MANUAL TRANSAXLE OIL (for Manual Transaxle)

12.DRAIN AUTOMATIC TRANSAXLE FLUID (for Automatic Transaxle)

12.DRAIN AUTOMATIC TRANSAXLE FLUID (for Automatic Transaxle)

11212

13.REMOVE NO. 2 CYLINDER HEAD COVER

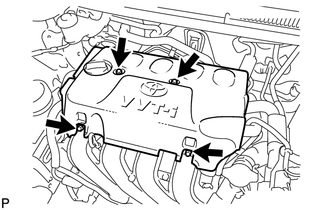

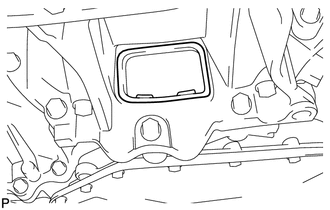

11212

13.REMOVE NO. 2 CYLINDER HEAD COVER

Remove the 4 nuts and No. 2 cylinder head cover.

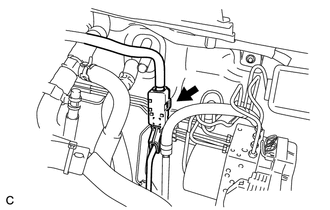

23826

14.DISCONNECT NO. 1 FUEL VAPOR FEED HOSE

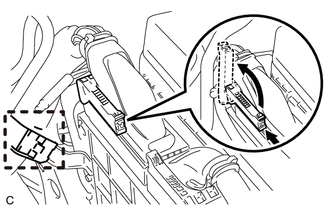

23826

14.DISCONNECT NO. 1 FUEL VAPOR FEED HOSE

Slide the clip and disconnect the No. 1 fuel vapor feed hose from the purge valve (purge VSV).

Disconnect the connector.

17705

15.REMOVE AIR CLEANER CAP WITH AIR CLEANER HOSE

17705

15.REMOVE AIR CLEANER CAP WITH AIR CLEANER HOSE

17701

16.REMOVE AIR CLEANER CASE SUB-ASSEMBLY

17701

16.REMOVE AIR CLEANER CASE SUB-ASSEMBLY

Remove the air cleaner filter element sub-assembly from the air cleaner case sub-assembly.

Disconnect the wire harness clamp from the air cleaner case sub-assembly.

Remove the 3 bolts and air cleaner case sub-assembly.

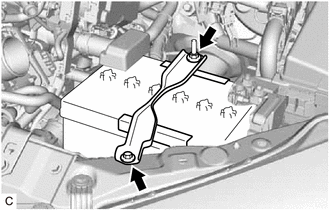

17.REMOVE BATTERY

17.REMOVE BATTERY

Loosen the nut, and disconnect the cable from the positive (+) battery terminal.

Remove the bolt, nut and battery clamp sub-assembly.

Remove the battery and battery tray from the battery carrier.

| *1 | Battery Clamp Bolt |

| *2 | Battery Carrier Support |

Remove the battery clamp bolt from the battery carrier support.

74411

18.REMOVE BATTERY CARRIER

74411

18.REMOVE BATTERY CARRIER

Disconnect the 2 wire harness clamps from the battery carrier.

Remove the 2 bolts and disconnect the radiator pipe from the battery carrier.

Remove the 4 bolts and battery carrier.

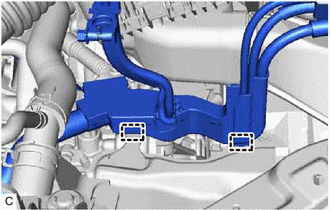

16571C

19.DISCONNECT NO. 1 RADIATOR HOSE

16571C

19.DISCONNECT NO. 1 RADIATOR HOSE

Slide the clip and disconnect the No. 1 radiator hose from the cylinder head sub-assembly.

16572D

20.DISCONNECT NO. 2 RADIATOR HOSE

16572D

20.DISCONNECT NO. 2 RADIATOR HOSE

Slide the clip and disconnect the No. 2 radiator hose from the water inlet.

33820B

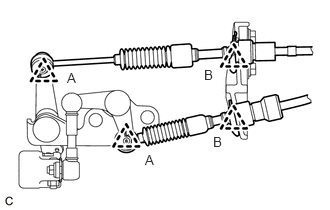

21.DISCONNECT TRANSMISSION CONTROL CABLE ASSEMBLY (for Manual Transaxle)

33820B

21.DISCONNECT TRANSMISSION CONTROL CABLE ASSEMBLY (for Manual Transaxle)

Remove the 2 clips (A) and disconnect the transmission control cable assembly from the manual transaxle assembly.

Remove the 2 clips (B) and disconnect the transmission control cable assembly from the control cable bracket assembly.

33820B

22.DISCONNECT TRANSMISSION CONTROL CABLE ASSEMBLY (for Automatic Transaxle)

33820B

22.DISCONNECT TRANSMISSION CONTROL CABLE ASSEMBLY (for Automatic Transaxle)

31470

23.SEPARATE CLUTCH RELEASE CYLINDER ASSEMBLY (for Manual Transaxle)

31470

23.SEPARATE CLUTCH RELEASE CYLINDER ASSEMBLY (for Manual Transaxle)

Remove the 4 bolts and clutch tube bracket, and separate the clutch release cylinder assembly.

32921

24.REMOVE INLET NO. 1 OIL COOLER TUBE (for Automatic Transaxle)

32921

24.REMOVE INLET NO. 1 OIL COOLER TUBE (for Automatic Transaxle)

32922

25.REMOVE OUTLET NO. 1 OIL COOLER TUBE (for Automatic Transaxle)

32922

25.REMOVE OUTLET NO. 1 OIL COOLER TUBE (for Automatic Transaxle)

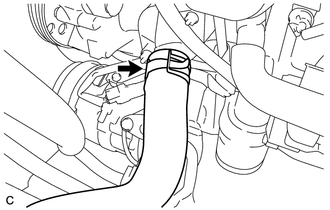

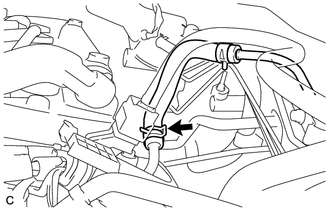

44774

26.DISCONNECT UNION TO CONNECTOR TUBE HOSE

44774

26.DISCONNECT UNION TO CONNECTOR TUBE HOSE

Slide the clip and disconnect the union to connector tube hose from the air tube.

87246

27.DISCONNECT OUTLET HEATER WATER HOSE

87246

27.DISCONNECT OUTLET HEATER WATER HOSE

87245

28.DISCONNECT INLET HEATER WATER HOSE

87245

28.DISCONNECT INLET HEATER WATER HOSE

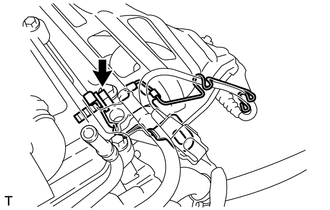

23901

29.DISCONNECT FUEL TUBE SUB-ASSEMBLY

23901

29.DISCONNECT FUEL TUBE SUB-ASSEMBLY

Disengage the claw and remove the No. 1 fuel pipe clamp.

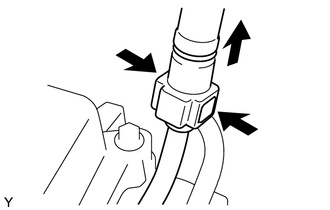

Pinch the retainer as shown in the illustration, then pull the fuel tube connector off the fuel pipe.

- NOTICE:

- ·

Remove any dirt and foreign matter from the fuel tube connector before performing this work.

·Do not allow any scratches or foreign matter to get on the parts when disconnecting them, as the fuel tube connector has O-rings that seal the fuel pipe.

·Perform this work by hand. Do not use any tools.

·Do not forcibly bend, kink or twist the nylon tube.

·Protect the disconnected part by covering it with a plastic bag after disconnecting the fuel tube sub-assembly.

·If the fuel tube connector and fuel pipe are stuck, push and pull to release them.

16361A

30.REMOVE V-RIBBED BELT

16361A

30.REMOVE V-RIBBED BELT

27020

31.REMOVE GENERATOR ASSEMBLY

27020

31.REMOVE GENERATOR ASSEMBLY

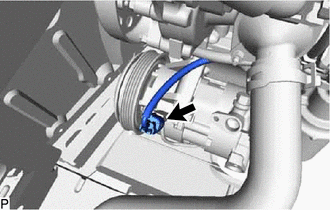

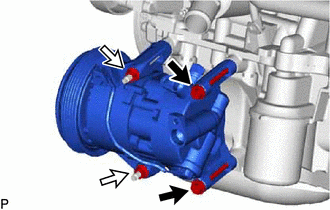

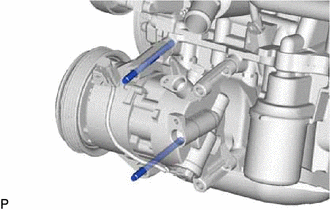

88310

32.SEPARATE COMPRESSOR ASSEMBLY WITH PULLEY

88310

32.SEPARATE COMPRESSOR ASSEMBLY WITH PULLEY

Disconnect the connector.

|

Bolt |

|

Nut |

Remove the 2 bolts and 2 nuts.

Using an E8 "TORX" socket wrench, remove the 2 stud bolts.

Separate the compressor assembly with pulley from the engine assembly.

- HINT:

-

Secure the compressor and hoses off to the side instead of discharging the A/C system.

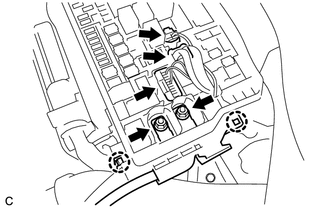

33.DISCONNECT WIRE HARNESS

33.DISCONNECT WIRE HARNESS

Disengage the wire harness clamp.

Pull up the lever and disconnect the ECM connector.

Remove the No. 1 engine room relay block cover from the engine room relay block and junction block assembly.

Remove the 2 nuts from the engine room relay block and junction block assembly.

Disconnect the 3 wire harness connectors.

Disengage the 2 claws to disconnect the wire harness from the engine room relay block and junction block assembly.

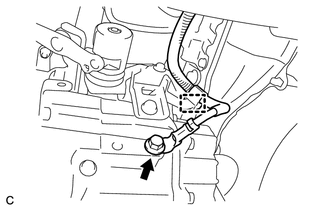

for Manual Transaxle:

Disengage the clamp to disconnect the engine wire from the engine mounting bracket LH.

Remove the bolt and disconnect the No. 3 engine wire from the manual transaxle assembly.

for Automatic Transaxle:

Disengage the clamp to disconnect the engine wire from the engine mounting bracket LH.

Remove the bolt and disconnect the No. 3 engine wire from the automatic transaxle assembly.

Make sure that no wire harness is connected between the vehicle body and engine assembly.

45259A

34.REMOVE COLUMN HOLE COVER SILENCER SHEET

45259A

34.REMOVE COLUMN HOLE COVER SILENCER SHEET

45260

35.SEPARATE NO. 2 STEERING INTERMEDIATE SHAFT ASSEMBLY

45260

35.SEPARATE NO. 2 STEERING INTERMEDIATE SHAFT ASSEMBLY

45025D

36.SEPARATE NO. 1 STEERING COLUMN HOLE COVER SUB-ASSEMBLY

45025D

36.SEPARATE NO. 1 STEERING COLUMN HOLE COVER SUB-ASSEMBLY

17141

37.REMOVE EXHAUST MANIFOLD

17141

37.REMOVE EXHAUST MANIFOLD

38.REMOVE DRIVE SHAFT ASSEMBLY

38.REMOVE DRIVE SHAFT ASSEMBLY

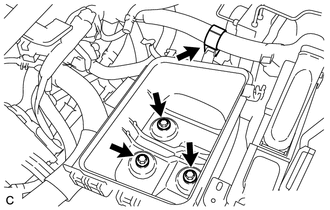

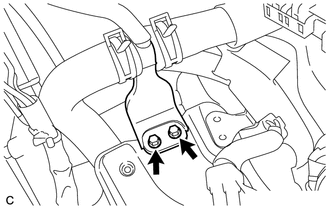

11361J

39.REMOVE FLYWHEEL HOUSING UNDER COVER

11361J

39.REMOVE FLYWHEEL HOUSING UNDER COVER

Remove the flywheel housing under cover from the oil pan sub-assembly.

32101G

40.REMOVE DRIVE PLATE AND TORQUE CONVERTER ASSEMBLY SETTING BOLT (for Automatic Transaxle)

32101G

40.REMOVE DRIVE PLATE AND TORQUE CONVERTER ASSEMBLY SETTING BOLT (for Automatic Transaxle)

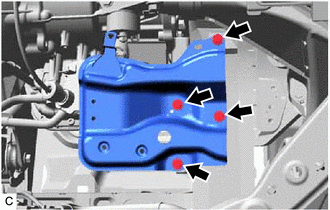

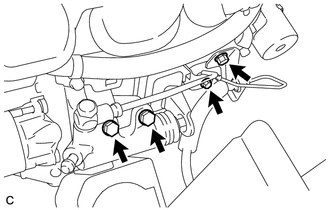

51201

41.REMOVE FRONT SUSPENSION CROSSMEMBER SUB-ASSEMBLY

51201

41.REMOVE FRONT SUSPENSION CROSSMEMBER SUB-ASSEMBLY

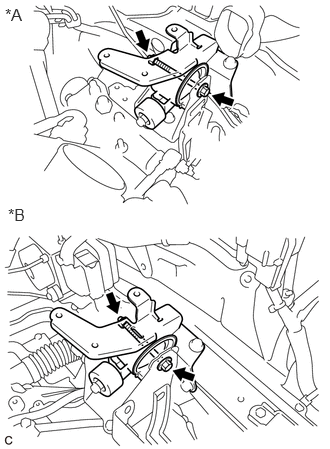

42.REMOVE ENGINE ASSEMBLY WITH TRANSAXLE

42.REMOVE ENGINE ASSEMBLY WITH TRANSAXLE

Set an engine lifter.

- NOTICE:

- ·

Using height adjustment attachments and plate lift attachments, place the engine assembly with transaxle horizontally.

·Do not perform any procedure while the engine assembly with transaxle is suspended because doing so may cause the engine assembly with transaxle to drop, resulting in injury. However, the engine assembly with transaxle needs to be suspended when it is installed to or removed from an engine stand.

Remove the center engine mounting member sub-assembly.

Click hereSuspension>FRONT SUSPENSION>FRONT SUSPENSION MEMBER>REMOVAL

Remove the 2 bolts and nut, and separate the engine mounting insulator sub-assembly RH.

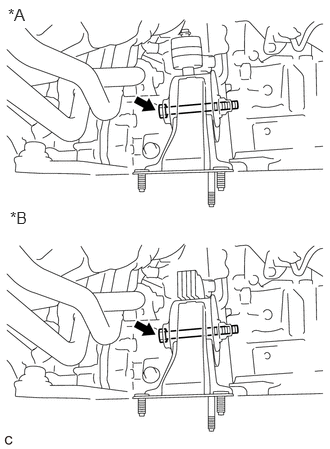

| *A | for Manual Transaxle |

| *B | for Automatic Transaxle |

Remove the through bolt, nut and separate the engine mounting insulator LH.

- HINT:

-

Because the nut has its own stopper, do not turn the nut. Loosen the through bolt with the nut secured.

Carefully remove the engine assembly with transaxle from the vehicle.

- NOTICE:

-

Make sure that the engine assembly with transaxle is clear of all wiring and hoses.

12361A

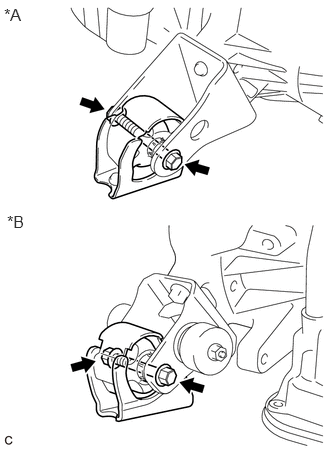

43.REMOVE FRONT ENGINE MOUNTING INSULATOR

12361A

43.REMOVE FRONT ENGINE MOUNTING INSULATOR

- HINT:

-

Perform this procedure only when replacement of the front engine mounting insulator is necessary.

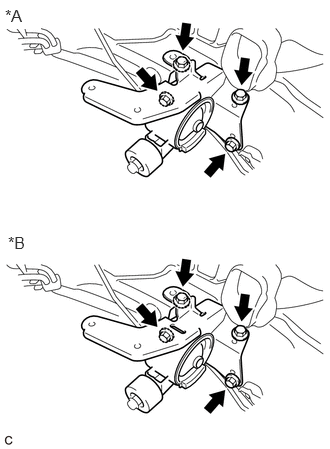

| *A | for Manual Transaxle |

| *B | for Automatic Transaxle |

Remove the through bolt, nut and front engine mounting insulator from the front engine mounting bracket.

- HINT:

-

Because the nut has its own stopper, do not turn the nut. Loosen the through bolt with the nut secured.

12371A

44.REMOVE REAR ENGINE MOUNTING INSULATOR

12371A

44.REMOVE REAR ENGINE MOUNTING INSULATOR

- HINT:

-

Perform this procedure only when replacement of the rear engine mounting insulator is necessary.

| *A | for Manual Transaxle |

| *B | for Automatic Transaxle |

Remove the through bolt and rear engine mounting insulator from the rear engine mounting bracket.

12372A

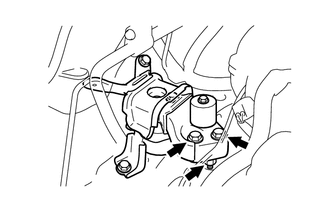

45.REMOVE ENGINE MOUNTING INSULATOR LH

12372A

45.REMOVE ENGINE MOUNTING INSULATOR LH

- HINT:

-

Perform this procedure only when replacement of the engine mounting insulator LH is necessary.

| *A | for Manual Transaxle |

| *B | for Automatic Transaxle |

Remove the 4 bolts and engine mounting insulator LH.

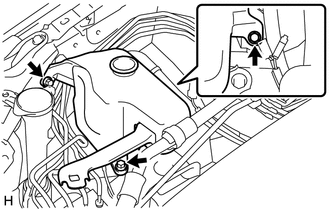

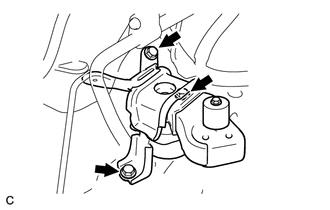

12305

46.REMOVE ENGINE MOUNTING INSULATOR SUB-ASSEMBLY RH

12305

46.REMOVE ENGINE MOUNTING INSULATOR SUB-ASSEMBLY RH

- HINT:

-

Perform this procedure only when replacement of the engine mounting insulator sub-assembly RH is necessary.

Disengage the clamp to separate the reserve hose.

Remove the reserve tank cap sub-assembly.

Remove the 3 bolts and radiator reserve tank assembly.

Remove the 3 bolts and engine mounting insulator sub-assembly RH.

47.REMOVE WIRE HARNESS CLAMP BRACKET

47.REMOVE WIRE HARNESS CLAMP BRACKET

Remove the bolt and wire harness clamp bracket.

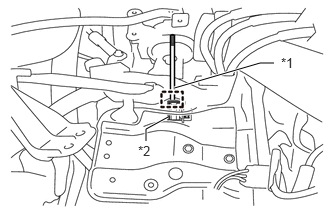

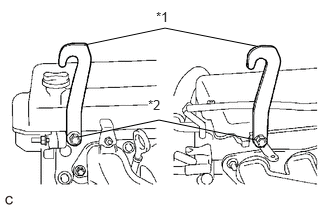

48.INSTALL ENGINE HANGER

48.INSTALL ENGINE HANGER

| *1 | No. 1 Engine Hanger (Part No.12281-21090) |

| *2 | Bolt (Part No. 91672-81025) |

Install the 2 No. 1 engine hangers with the 2 bolts.

- Torque:

- 43 N*m (438 kgf*cm, 32 ft.*lbf)

Attach an engine sling device and hang the engine assembly with transaxle with a chain block.

- NOTICE:

- ·

Pay attention to the angle of the sling device as the engine assembly or 2 No. 1 engine hangers may be damaged or deformed if the angle is incorrect.

·Do not perform any procedure while the engine assembly with transaxle is suspended because doing so may cause the engine assembly with transaxle to drop, resulting in injury. However, the engine assembly with transaxle needs to be suspended when it is installed to or removed from an engine stand.

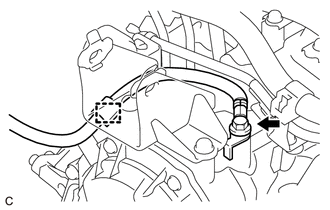

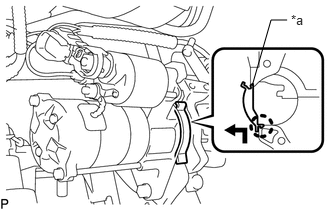

11363A

49.REMOVE FLYWHEEL HOUSING SIDE COVER

11363A

49.REMOVE FLYWHEEL HOUSING SIDE COVER

| *a | Protruding Portion |

Push up the flywheel housing side cover as shown in the illustration to disengage the claw, and remove the flywheel housing side cover.

28100

50.REMOVE STARTER ASSEMBLY

28100

50.REMOVE STARTER ASSEMBLY

82121

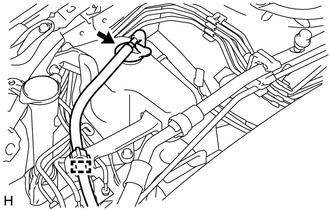

51.REMOVE ENGINE WIRE

82121

51.REMOVE ENGINE WIRE

Remove the engine wire from the engine assembly with transaxle.

30300

52.REMOVE MANUAL TRANSAXLE ASSEMBLY (for Manual Transaxle)

30300

52.REMOVE MANUAL TRANSAXLE ASSEMBLY (for Manual Transaxle)

31210

53.REMOVE CLUTCH COVER ASSEMBLY (for Manual Transaxle)

31210

53.REMOVE CLUTCH COVER ASSEMBLY (for Manual Transaxle)

31250

54.REMOVE CLUTCH DISC ASSEMBLY (for Manual Transaxle)

31250

54.REMOVE CLUTCH DISC ASSEMBLY (for Manual Transaxle)

13405

55.REMOVE FLYWHEEL SUB-ASSEMBLY (for Manual Transaxle)

13405

55.REMOVE FLYWHEEL SUB-ASSEMBLY (for Manual Transaxle)

30500

56.REMOVE AUTOMATIC TRANSAXLE ASSEMBLY (for Automatic Transaxle)

30500

56.REMOVE AUTOMATIC TRANSAXLE ASSEMBLY (for Automatic Transaxle)

32101

57.REMOVE DRIVE PLATE AND RING GEAR SUB-ASSEMBLY (for Automatic Transaxle)

32101

57.REMOVE DRIVE PLATE AND RING GEAR SUB-ASSEMBLY (for Automatic Transaxle)

58.INSTALL ENGINE TO ENGINE STAND

58.INSTALL ENGINE TO ENGINE STAND

Install the engine assembly to an engine stand.

- NOTICE:

- ·

Adjust the angle of the sling device carefully to prevent the engine assembly or engine hangers from deforming or becoming damaged.

·Servicing an engine assembly while it is hanging is dangerous. This can be done only when installing/removing the engine assembly to/from an engine stand.

59.REMOVE ENGINE HANGER

59.REMOVE ENGINE HANGER

Remove the 2 bolts, 2 No. 1 engine hangers.