2NZ-FE ENGINE MECHANICAL REAR CRANKSHAFT OIL SEAL REMOVAL

CAUTION / NOTICE / HINT

- NOTICE:

-

for Manual Transaxle:

-

When the manual transaxle assembly is removed, be sure to use a new clutch release with bearing cylinder assembly and new installation bolts. Removal of the manual transaxle assembly allows the compressed clutch release with bearing cylinder assembly to return to its original position, and dust could damage the seal of the clutch release with bearing cylinder assembly, possibly causing clutch fluid leaks.

PROCEDURE

31250

1.REMOVE CLUTCH DISC ASSEMBLY (for Manual Transaxle)

31250

1.REMOVE CLUTCH DISC ASSEMBLY (for Manual Transaxle)

30500

2.REMOVE AUTOMATIC TRANSAXLE ASSEMBLY (for Automatic Transaxle)

30500

2.REMOVE AUTOMATIC TRANSAXLE ASSEMBLY (for Automatic Transaxle)

13405

3.REMOVE FLYWHEEL SUB-ASSEMBLY (for Manual Transaxle)

13405

3.REMOVE FLYWHEEL SUB-ASSEMBLY (for Manual Transaxle)

Using height adjustment attachments and plate lift attachments, place the engine assembly on a flat, level surface.

- NOTICE:

- ·

Using height adjustment attachments and plate lift attachments, place the engine assembly horizontally.

·Using an engine sling device and engine lift, secure the engine assembly before servicing.

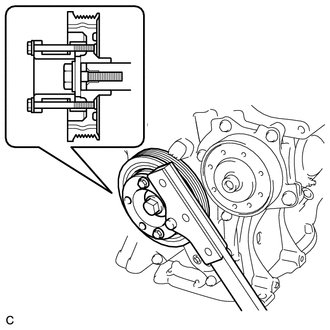

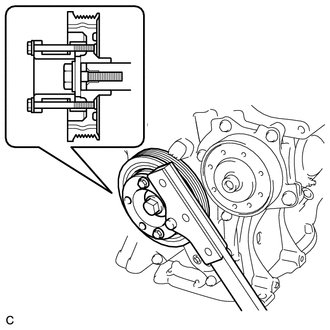

Using SST, hold the crankshaft damper sub-assembly.

- SST

- 09213-14010 09330-00021

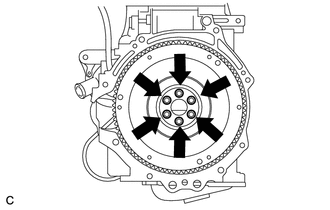

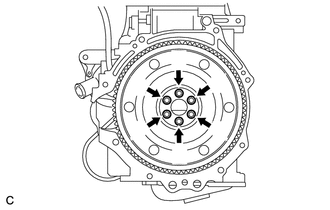

Remove the 6 bolts and flywheel sub-assembly from the crankshaft.

32101

4.REMOVE DRIVE PLATE AND RING GEAR SUB-ASSEMBLY (for Automatic Transaxle)

32101

4.REMOVE DRIVE PLATE AND RING GEAR SUB-ASSEMBLY (for Automatic Transaxle)

Using height adjustment attachments and plate lift attachments, place the engine assembly on a flat, level surface.

- NOTICE:

- ·

Using height adjustment attachments and plate lift attachments, place the engine assembly horizontally.

·Using an engine sling device and engine lift, secure the engine assembly before servicing.

Using SST, hold the crankshaft damper sub-assembly.

- SST

- 09213-14010 09330-00021

Remove the 6 bolts, rear drive plate spacer, drive plate and ring gear sub-assembly and front drive plate spacer from the crankshaft.

11401L

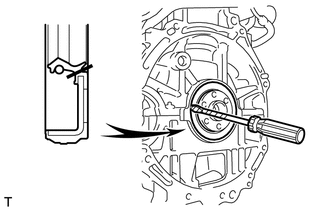

5.REMOVE REAR ENGINE OIL SEAL

11401L

5.REMOVE REAR ENGINE OIL SEAL

| *a | Protective Tape |

| *b | Cut Position |

Using a knife, cut off the lip of the rear engine oil seal.

Using a screwdriver, pry out the rear engine oil seal.

- NOTICE:

-

After removal, check the crankshaft for damage. If damaged, smooth the surface with 400-grit sandpaper.

- HINT:

-

Tape the screwdriver tip before use.