U441E AUTOMATIC TRANSMISSION / TRANSAXLE AUTOMATIC TRANSAXLE ASSEMBLY INSTALLATION

PROCEDURE

83181G

1.INSTALL SPEEDOMETER SENSOR

83181G

1.INSTALL SPEEDOMETER SENSOR

Apply ATF to a new O-ring and install it to the speedometer sensor.

Install the speedometer driven gear to the speedometer sensor with the clip.

Install the speedometer sensor to the automatic transaxle assembly with the bolt.

- Torque:

- 11.3 N*m (115 kgf*cm, 8 ft.*lbf)

33829

2.INSTALL TRANSMISSION CONTROL CABLE SUPPORT

33829

2.INSTALL TRANSMISSION CONTROL CABLE SUPPORT

Install the transmission control cable support to the automatic transaxle assembly with the bolt.

- Torque:

- 12 N*m (122 kgf*cm, 9 ft.*lbf)

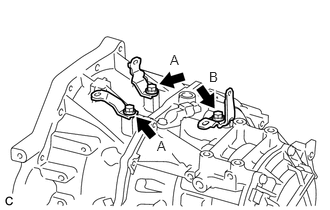

3.INSTALL WIRE HARNESS CLAMP BRACKET

3.INSTALL WIRE HARNESS CLAMP BRACKET

Install the 3 wire harness clamp brackets to the automatic transaxle assembly with the 3 bolts.

- Torque:

- Bolt (A) : 12.8 N*m (131 kgf*cm, 9 ft.*lbf)

- Bolt (B) : 8.4 N*m (86 kgf*cm, 74 in.*lbf)

4.INSPECT TORQUE CONVERTER ASSEMBLY

4.INSPECT TORQUE CONVERTER ASSEMBLY

5.INSTALL TORQUE CONVERTER ASSEMBLY

5.INSTALL TORQUE CONVERTER ASSEMBLY

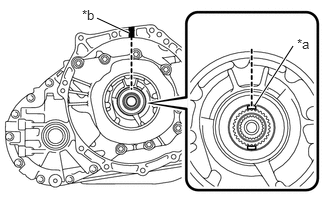

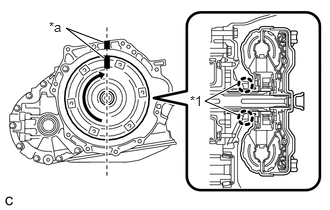

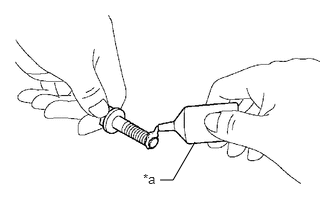

| *a | Key |

| *b | Matchmark |

Turn the front oil pump drive gear so that the key is at the top and place a matchmark on the transaxle housing to indicate the position of the key.

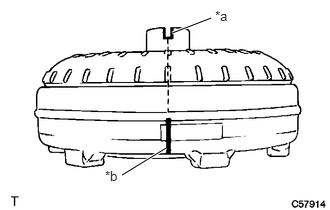

| *a | Groove |

| *b | Matchmark |

Place a matchmark on the torque converter assembly so that the position of its groove is clearly indicated.

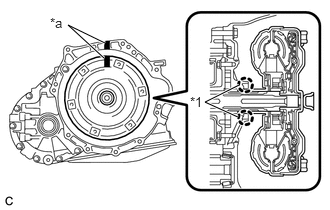

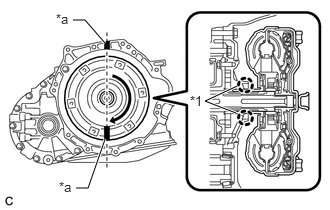

| *1 | Front Oil Pump Oil Seal |

| *a | Matchmark |

Align the matchmark on the transaxle housing with the one on the torque converter assembly and engage the splines of the input shaft with the turbine runner splines.

- NOTICE:

- ·

Install the torque converter assembly to the input shaft while keeping it horizontal.

·Do not damage the front oil pump oil seal.

| *1 | Front Oil Pump Oil Seal |

| *a | Matchmark |

Rotate the torque converter assembly approximately 180° and engage the splines of the stator shaft with the stator assembly.

- NOTICE:

- ·

Install the torque converter assembly to the input shaft while keeping it horizontal.

·Do not damage the front oil pump oil seal.

| *1 | Front Oil Pump Oil Seal |

| *a | Matchmark |

Rotate the torque converter assembly approximately 180° again, align the matchmark on the torque converter assembly with the one on the housing and insert the groove of the torque converter assembly into the key of the oil pump drive gear.

- NOTICE:

- ·

Do not push the torque converter assembly excessively when rotating it.

·Install the torque converter assembly to the input shaft while keeping it horizontal.

·Do not damage the front oil pump oil seal.

Clean the drive plate and torque converter assembly setting bolt holes.

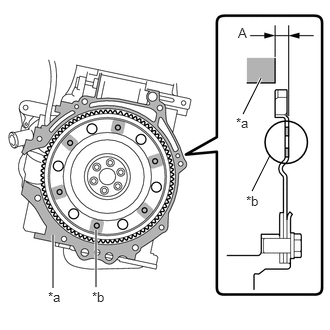

| *a | Engine Surface |

| *b | Drive Plate Surface |

Using a vernier caliper and straightedge, measure the dimension (A) between the automatic transaxle assembly contact surface of the engine assembly*a and the torque converter assembly contact surfaces of the drive plate*b.

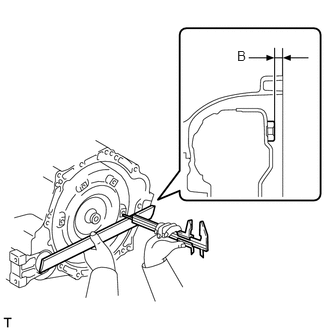

Using a vernier caliper and straightedge, measure the dimension (B) shown in the illustration and check that the dimension (B) is more than the dimension (A), which was measured in the previous step.

- Standard:

A + 1 mm (0.0394 in.) or more

- NOTICE:

- ·

Make sure to deduct the thickness of the straightedge.

·If the automatic transaxle assembly is installed to the engine assembly with the torque converter assembly not sufficiently inserted, the torque converter assembly may be damaged.

·Do not include the thickness of the set block.

30500

6.INSTALL AUTOMATIC TRANSAXLE ASSEMBLY

30500

6.INSTALL AUTOMATIC TRANSAXLE ASSEMBLY

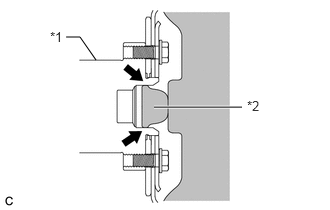

| *1 | Crankshaft |

| *2 | Torque Converter Assembly Centerpiece |

Apply clutch spline grease to the surface of the crankshaft that contacts the torque converter assembly centerpiece.

- Clutch Spline Grease:

Toyota Genuine Clutch Spline Grease or equivalent

- Maximum Grease Amount:

Approximately 1 g (0.0353 oz)

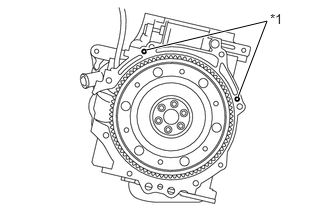

| *1 | Knock Pin |

Confirm that the 2 knock pins are installed to the engine assembly and are not damaged.

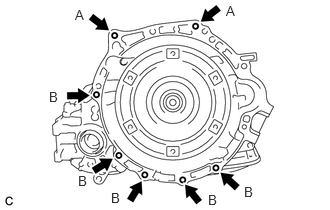

Install the automatic transaxle assembly to the engine assembly with the 7 bolts.

- Torque:

- 29.5 N*m (301 kgf*cm, 22 ft.*lbf)

- NOTICE:

- ·

Make sure that the wire harness or similar items are not pinched between the contact surfaces.

·Do not use excess force when installing the automatic transaxle assembly.

·When mounting the automatic transaxle assembly to the engine assembly, make sure to securely fit the 2 knock pins into the knock holes.

·Check that the torque converter assembly rotates.

·When tightening the bolts, be sure that the mating surfaces of the engine assembly and the automatic transaxle assembly are in close contact with one another.

- HINT:

- ·

Bolt (A): Install from automatic transaxle assembly side

·Bolt (B): Install from engine assembly side

28100

7.INSTALL STARTER ASSEMBLY

28100

7.INSTALL STARTER ASSEMBLY

11363A

8.INSTALL FLYWHEEL HOUSING SIDE COVER

11363A

8.INSTALL FLYWHEEL HOUSING SIDE COVER

12321B

9.INSTALL DRIVE SHAFT HEAT INSULATOR SUB-ASSEMBLY

12321B

9.INSTALL DRIVE SHAFT HEAT INSULATOR SUB-ASSEMBLY

Install the drive shaft heat insulator sub-assembly to the engine assembly with the bolt and nut.

- Torque:

- 17.6 N*m (179 kgf*cm, 13 ft.*lbf)

35013

10.INSTALL TRANSMISSION OIL FILLER TUBE SUB-ASSEMBLY

35013

10.INSTALL TRANSMISSION OIL FILLER TUBE SUB-ASSEMBLY

Coat a new O-ring with ATF and install it to the transmission oil filler tube sub-assembly.

- NOTICE:

-

Be careful not to damage or twist the O-ring.

Install the transmission oil filler tube sub-assembly to the automatic transaxle assembly with the bolt.

- Torque:

- 5.5 N*m (56 kgf*cm, 49 in.*lbf)

- NOTICE:

-

Make sure that the O-ring is not cracked or moved out of position during installation.

Connect the breather plug hose to the transmission oil filler tube sub-assembly.

35103

11.INSTALL TRANSMISSION OIL LEVEL DIPSTICK SUB-ASSEMBLY

35103

11.INSTALL TRANSMISSION OIL LEVEL DIPSTICK SUB-ASSEMBLY

Install the transmission oil level dipstick sub-assembly to the transmission oil filler tube sub-assembly.

33823

12.INSTALL NO. 1 TRANSMISSION CONTROL CABLE BRACKET

33823

12.INSTALL NO. 1 TRANSMISSION CONTROL CABLE BRACKET

Install the No. 1 transmission control cable bracket to the automatic transaxle assembly with the 2 bolts.

- Torque:

- 12 N*m (122 kgf*cm, 9 ft.*lbf)

32924

13.INSTALL NO. 2 OIL COOLER TUBE CLAMP

32924

13.INSTALL NO. 2 OIL COOLER TUBE CLAMP

Temporarily install the outlet No. 1 oil cooler tube to the oil cooler tube union.

Temporarily install the inlet No. 1 oil cooler tube to the oil cooler tube union.

Install the No. 2 oil cooler tube clamp to the transmission oil filler tube sub-assembly with the bolt.

- Torque:

- 5.5 N*m (56 kgf*cm, 49 in.*lbf)

32922

14.INSTALL OUTLET NO. 1 OIL COOLER TUBE

32922

14.INSTALL OUTLET NO. 1 OIL COOLER TUBE

Using a 14 mm union nut wrench, install the outlet No. 1 oil cooler tube to the automatic transaxle assembly while holding the oil cooler tube union with a wrench.

- Torque:

- 34 N*m (347 kgf*cm, 25 ft.*lbf)

32921

15.INSTALL INLET NO. 1 OIL COOLER TUBE

32921

15.INSTALL INLET NO. 1 OIL COOLER TUBE

Using a 14 mm union nut wrench, install the inlet No. 1 oil cooler tube to the automatic transaxle assembly while holding the oil cooler tube union with a wrench.

- Torque:

- 34 N*m (347 kgf*cm, 25 ft.*lbf)

12325A

16.INSTALL ENGINE MOUNTING BRACKET LH

12325A

16.INSTALL ENGINE MOUNTING BRACKET LH

Clean the 3 bolts and the installation holes in the engine mounting bracket LH.

| *a | Adhesive |

Apply adhesive to 2 or 3 threads on the ends of the 3 bolts.

- Adhesive:

Toyota Genuine Adhesive 1324, Three Bond 1324 or equivalent

- NOTICE:

-

In order to ensure proper installation of the 3 bolts, apply adhesive to the 3 bolts and install them within 10 minutes of adhesive application.

Install the engine mounting bracket LH to the automatic transaxle assembly with the 3 bolts.

- Torque:

- 52 N*m (530 kgf*cm, 38 ft.*lbf)

12321A

17.INSTALL REAR ENGINE MOUNTING BRACKET

12321A

17.INSTALL REAR ENGINE MOUNTING BRACKET

Install the rear engine mounting bracket to the automatic transaxle assembly with the 3 bolts.

- Torque:

- 64 N*m (653 kgf*cm, 47 ft.*lbf)

12311A

18.INSTALL FRONT ENGINE MOUNTING BRACKET

12311A

18.INSTALL FRONT ENGINE MOUNTING BRACKET

Install the front engine mounting bracket to the automatic transaxle assembly with the 2 bolts.

- Torque:

- 45 N*m (459 kgf*cm, 33 ft.*lbf)

19.CONNECT ENGINE WIRE

19.CONNECT ENGINE WIRE

Engage the 5 clamps.

Connect the speedometer sensor connector.

Connect the transmission revolution sensor connector.

Connect the transmission wire connector.

Connect the park/neutral position switch assembly connector.

12361A

20.TEMPORARILY INSTALL FRONT ENGINE MOUNTING INSULATOR

12361A

20.TEMPORARILY INSTALL FRONT ENGINE MOUNTING INSULATOR

12371A

21.TEMPORARILY INSTALL REAR ENGINE MOUNTING INSULATOR

12371A

21.TEMPORARILY INSTALL REAR ENGINE MOUNTING INSULATOR

22.INSTALL ENGINE ASSEMBLY WITH TRANSAXLE

22.INSTALL ENGINE ASSEMBLY WITH TRANSAXLE

51204A

23.TEMPORARILY INSTALL CENTER ENGINE MOUNTING MEMBER SUB-ASSEMBLY

51204A

23.TEMPORARILY INSTALL CENTER ENGINE MOUNTING MEMBER SUB-ASSEMBLY

51201

24.INSTALL FRONT SUSPENSION CROSSMEMBER SUB-ASSEMBLY

51201

24.INSTALL FRONT SUSPENSION CROSSMEMBER SUB-ASSEMBLY

51204A

25.FULLY INSTALL CENTER ENGINE MOUNTING MEMBER SUB-ASSEMBLY

51204A

25.FULLY INSTALL CENTER ENGINE MOUNTING MEMBER SUB-ASSEMBLY

12371A

26.FULLY INSTALL REAR ENGINE MOUNTING INSULATOR

12371A

26.FULLY INSTALL REAR ENGINE MOUNTING INSULATOR

12361A

27.FULLY INSTALL FRONT ENGINE MOUNTING INSULATOR

12361A

27.FULLY INSTALL FRONT ENGINE MOUNTING INSULATOR

28.REMOVE ENGINE HANGER

28.REMOVE ENGINE HANGER

29.INSTALL WIRE HARNESS CLAMP BRACKET

29.INSTALL WIRE HARNESS CLAMP BRACKET

32101A

30.INSTALL DRIVE PLATE AND TORQUE CONVERTER ASSEMBLY SETTING BOLT

32101A

30.INSTALL DRIVE PLATE AND TORQUE CONVERTER ASSEMBLY SETTING BOLT

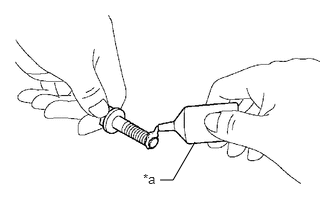

Clean the threads of the 6 drive plate and torque converter assembly setting bolts.

| *a | Adhesive |

Apply a few drops of adhesive to 2 or 3 threads at the tip of each of the 6 drive plate and torque converter assembly setting bolts.

- Adhesive:

Toyota Genuine Adhesive 1324, Three Bond 1324 or equivalent

- NOTICE:

-

In order to ensure proper installation of the 6 drive plate and torque converter assembly setting bolts, apply adhesive to the 6 drive plate and torque converter assembly setting bolts and install them within 10 minutes of adhesive application.

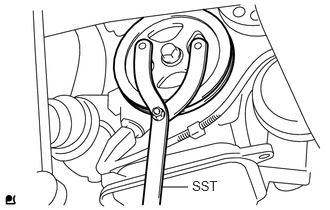

Turn the crankshaft to gain access to the installation locations of the 6 drive plate and torque converter assembly setting bolts and install each bolt while holding the crankshaft pulley with SST.

- SST

- 09960-10010 (09962-01000, 09963-01000)

- Torque:

- 28 N*m (286 kgf*cm, 21 ft.*lbf)

- NOTICE:

- ·

First install the black-colored bolt, and then the remaining 5 silver-colored bolts.

·Do not start the engine for at least 1 hour after installing the drive plate and torque converter assembly setting bolts.

11361J

31.INSTALL FLYWHEEL HOUSING UNDER COVER

11361J

31.INSTALL FLYWHEEL HOUSING UNDER COVER

32.RESET MEMORY (AT initialization)

32.RESET MEMORY (AT initialization)