2NZ-FE ENGINE CONTROL SFI SYSTEM P1603 Engine Stall History P1605 Rough Idling

DESCRIPTION

- P1603 (for A/T models)

After starting the engine, this DTC is stored when the engine stops without the ignition switch being operated.

Using the GTS, the conditions present when the DTC was stored can be confirmed by referring to the freeze frame data. Freeze frame data records engine conditions when a malfunction occurs. This information can be useful when troubleshooting.

It is necessary to check if the vehicle has run out of fuel before performing troubleshooting, as this DTC is also stored when the engine stalls due to running out of fuel.

- P1605

This DTC is stored if the engine speed drops below the set speed.

Using the GTS, the conditions present when the DTC was stored can be confirmed by referring to the freeze frame data. Freeze frame data records engine conditions when a malfunction occurs. This information can be useful when troubleshooting.

It is necessary to check if the vehicle ran out of fuel before performing troubleshooting, as this DTC is also stored when idling is unstable due to running out of fuel.

| DTC No. | Detection Item | DTC Detection Condition | Trouble Area | MIL | Memory |

|---|---|---|---|---|---|

| P1603 | Engine Stall History | After monitoring for startability problems (P1604) finishes and 2 seconds or more have elapsed after starting the engine, with the engine running, the engine stops (the engine speed drops to 200 rpm or less) without the ignition switch being operated for 0.5 seconds or more (1 trip detection logic). | ·

Air leak in intake system ·

Purge VSV ·

Brake booster assembly ·

Mass air flow meter sub-assembly ·

Engine coolant temperature sensor ·

Thermostat ·

Power supply circuit (purge VSV, heated oxygen sensor, fuel injector assembly, ignition coil assembly) ·

Fuel pump ·

Fuel pump control circuit ·

Fuel line ·

PCV valve and hose ·

Camshaft timing oil control valve assembly ·

Knock control sensor ·

Ignition system ·

Air conditioning system ·

Power steering system ·

Electrical load signal system ·

Charging system ·

A/T system ·

Park/neutral position switch assembly ·

ECM ·

Immobiliser system ·

Wire harness or connector |

Does not come on | DTC stored |

| P1605 | Rough Idling | After 5 seconds or more have elapsed after starting the engine, with the engine running, the engine speed drops to 400 rpm or less (1 trip detection logic). | ·

Air leak in intake system ·

Purge VSV ·

Brake booster assembly ·

Mass air flow meter sub-assembly ·

Engine coolant temperature sensor ·

Thermostat ·

Power supply circuit (purge VSV, heated oxygen sensor, fuel injector assembly, ignition coil assembly) ·

Fuel pump ·

Fuel pump control circuit ·

Fuel line ·

PCV valve and hose ·

Camshaft timing oil control valve assembly ·

Knock control sensor ·

Ignition system ·

Air conditioning system ·

Power steering system ·

Electrical load signal system ·

Charging system ·

A/T system* ·

Park/neutral position switch assembly* ·

ECM ·

Immobiliser system ·

Wire harness or connector |

Does not come on | DTC stored |

*: for A/T system

CAUTION / NOTICE / HINT

- HINT:

- ·

In contrast to normal malfunction diagnosis for components, circuits and systems, DTCs P1603 and P1605 are used to determine the malfunctioning area from the problem symptoms and freeze frame data when the user mentions problems such as engine stall.

As these DTCs can be stored as a result of certain user actions, even if these DTCs are output, if the customer makes no mention of problems, clear these DTCs without performing any troubleshooting and return the vehicle to the customer.

·If any other DTCs are output, perform troubleshooting for those DTCs first.

·Use any information from the customer problem analysis about the condition of the vehicle at the time when the problem occurred (how the engine stopped, conditions when the engine was restarted, etc.) as a reference.

Symptom Suspected Area Engine vibration occurs and engine stops Air fuel ratio abnormal Engine stops with no engine vibration Ignition system, injection stoppage, high load from external parts Engine can be started with accelerator pedal depressed Insufficient air volume Rough idling after engine started Air fuel ratio abnormal, abnormal combustion

·Read freeze frame data using the GTS. Freeze frame data records engine conditions when a malfunction occurs. This information can be useful when troubleshooting.

·When confirming the freeze frame data, be sure to check all 5 sets of freeze frame data.

Click hereEngine / Hybrid System>2NZ-FE ENGINE CONTROL>SFI SYSTEM>FREEZE FRAME DATA

·When DTC P1603 (Engine Stall History) is stored, DTC P1605 (Rough Idling) is also stored. When confirming freeze frame data, check DTC P1605. The ECM stores DTC P1605 first. Therefore, 5 sets of freeze frame data can be confirmed through DTC P1605, enabling the technician to obtain more information.

·When confirming freeze frame data, if there are multiple items related to the cause of the malfunction, perform troubleshooting for all related items.

·Try to operate the vehicle under the conditions recorded in the freeze frame data which were present when the malfunction occurred. Confirm the data at this time and the data when the engine is idling (engine warmed up, no load, and shift lever in D or neutral) and compare these data with the freeze frame data.

·Inspections take into account the fact that the malfunction may not have reoccurred and place emphasis on checking the vehicle conditions present at the time when the malfunction occurred.

·When performing inspections, jiggle the relevant wire harnesses and connectors in an attempt to reproduce malfunctions that do not always occur.

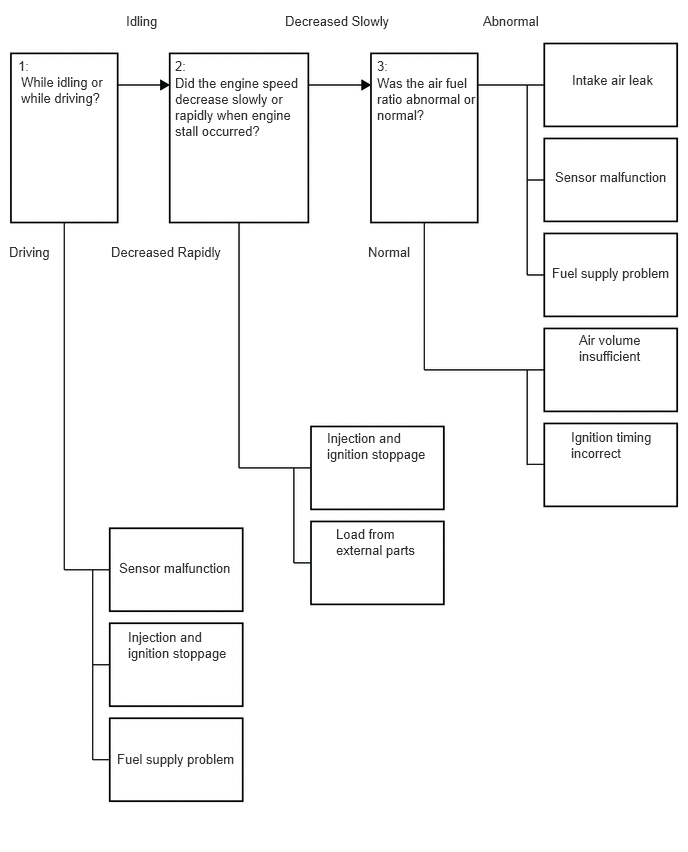

- Inspection flow:

Using freeze frame data, narrow down the parts to be inspected according to the vehicle conditions at the time when the malfunction occurred.

- P1603:

If the engine stalled when the intake air volume was low (during idling or deceleration), there may be a decrease in torque due to an incorrect air fuel ratio, etc.

If the engine stalled when the intake air volume was high (during driving or acceleration), there may be a major malfunction such as continuous misfire due to ignition stoppage, fuel injection stoppage, etc. and the torque drops to zero.

If the engine speed decreased slowly, there may have been a decrease in torque due to an air fuel ratio that was incorrect (by approximately 20 to 30%), etc.

If the engine speed decreased rapidly, there may have been a malfunction such as when the engine misfires almost continuously due to ignition stoppage, fuel injection stoppage, etc., or when the external load increases due to an external part malfunctioning.

If the air fuel ratio is abnormal, there may have been an intake air leak, sensor malfunction, or fuel supply problem.

If the air fuel ratio was normal, the air volume may have been insufficient or the ignition timing may have been incorrect.

P1603 inspection flow: Narrow down the parts to be inspected according to the vehicle conditions at the time when the malfunction occurred (freeze frame data).

| Vehicle State | Engine Speed | Suspected Area | Primary Parts to Inspect | Procedure | |

|---|---|---|---|---|---|

| Idling or decelerating | Slowly decreases and engine stalls | Ignition system abnormal | Igniter abnormal | ·

Power supply circuit ·

Ignition coil assembly ·

Spark plug |

10, 38, 53 |

| Air fuel ratio abnormal | Air suction | ·

Intake system connections ·

Purge VSV system ·

Brake booster assembly |

5 to 9 | ||

| Sensor malfunction (value from sensor too lean) | ·

Mass air flow meter sub-assembly ·

Engine coolant temperature sensor ·

Heated oxygen sensor system ·

Thermostat |

11 to 23 | |||

| Sensor malfunction (value from sensor too rich) | 39 to 51 | ||||

| Fuel supply problem | ·

Fuel pump control circuit ·

Purge VSV system ·

Fuel line ·

ECM |

24 to 37 | |||

| Intake air volume insufficient | Problem with air passage | ·

Intake system connections ·

Mass air flow meter sub-assembly ·

Brake booster assembly ·

PCV valve and hose ·

Purge VSV system |

54 to 56 | ||

| Excessive valve overlap | Camshaft timing oil control valve assembly | 57, 58 | |||

| Ignition timing incorrect | Does not operate as expected | ·

Knock control sensor ·

Engine coolant temperature sensor ·

Mass air flow meter sub-assembly |

59 to 63 | ||

| Rapidly decreases and engine stalls | Ignition and injection stops (electrical system malfunction) | Power temporarily cut | Power supply circuit (fuel injector assembly, ignition coil assembly) | 64, 65 | |

| External part malfunctioning | Increase in load | ·

Air conditioning system ·

Electrical load signal system ·

Power steering system ·

A/T system ·

Park/neutral position switch assembly |

66 to 69 | ||

| Accelerating | - | Crankshaft position sensor or camshaft position sensor malfunction | Power temporarily cut | Check DTCs | 1 |

| Mass air flow meter sub-assembly | Foreign matter adhesion | Mass air flow meter sub-assembly | 70 to 73 | ||

| Ignition and injection stops (electrical system malfunction) | Power temporarily cut | Power supply circuit (fuel injector assembly, ignition coil assembly) | 74, 75 | ||

| Fuel supply problem | Fuel leak, clog | ·

Fuel pump control system ·

Fuel line |

76 to 80 | ||

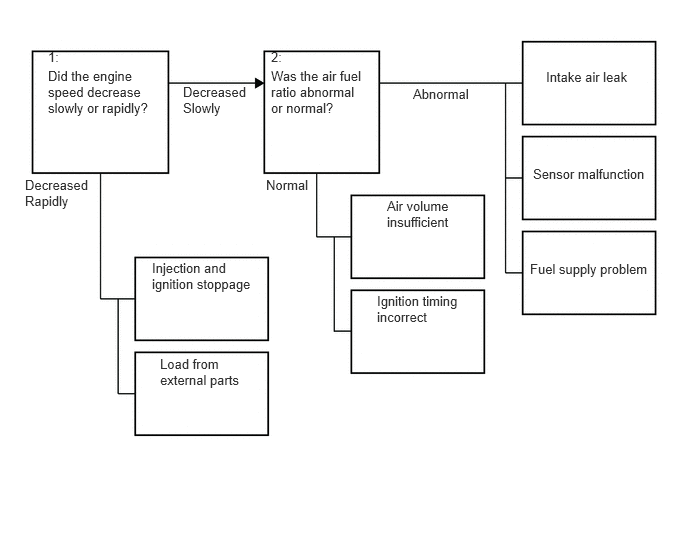

- P1605:

If the engine speed decreased slowly, there may have been a decrease in torque due to an air fuel ratio that was incorrect (by approximately 20 to 30%), etc.

If the engine speed decreased rapidly, there may have been a malfunction such as when the engine misfires almost continuously due to ignition stoppage, fuel injection stoppage, etc., or when the external load increases due to an external part malfunctioning.

If the air fuel ratio is abnormal, there may have been an intake air leak, sensor malfunction, or fuel supply problem.

If the air fuel ratio was normal, the air volume may have been insufficient or the ignition timing may have been incorrect.

P1605 inspection flow: Narrow down the parts to be inspected according to the vehicle conditions at the time when the malfunction occurred (freeze frame data).

| Engine Speed | Suspected Area | Primary Parts to Inspect | Procedure | |

|---|---|---|---|---|

| Slowly decreases | Ignition system abnormal | Igniter abnormal | ·

Power supply circuit ·

Ignition coil assembly ·

Spark plug |

10, 38, 53 |

| Air fuel ratio abnormal | Air suction | ·

Intake system connections ·

Purge VSV system ·

Brake booster assembly |

5 to 9 | |

| Sensor malfunction (value from sensor too lean) | ·

Mass air flow meter sub-assembly ·

Engine coolant temperature sensor ·

Heated oxygen sensor system ·

Thermostat |

11 to 23 | ||

| Sensor malfunction (value from sensor too rich) | 39 to 51 | |||

| Fuel supply problem | ·

Fuel pump control circuit ·

Purge VSV system ·

Fuel line ·

ECM |

24 to 37 | ||

| Intake air volume insufficient | Problem with air passage | ·

Intake system connections ·

Mass air flow meter sub-assembly ·

Brake booster assembly ·

PCV valve and hose ·

Purge VSV system |

54 to 56 | |

| Excessive valve overlap | Camshaft timing oil control valve assembly | 57, 58 | ||

| Ignition timing incorrect | Does not operate as expected | ·

Knock control sensor ·

Engine coolant temperature sensor ·

Mass air flow meter sub-assembly |

59 to 63 | |

| Rapidly decreases | Ignition and injection stops (electrical system malfunction) | Power temporarily cut | Power supply circuit (fuel injector assembly, ignition coil assembly) | 64, 65 |

| External part malfunctioning | Increase in load | ·

Air conditioning system ·

Electrical load signal system ·

Power steering system ·

A/T system* ·

Park/neutral position switch assembly* |

66 to 69 | |

*: for A/T system

- NOTICE:

-

Inspect the fuses for circuits related to this system before performing the following procedure.

PROCEDURE

Connect the GTS to the DLC3.

Turn the ignition switch to ON.

Turn the GTS on.

Enter the following menus: Powertrain / Engine and ECT / Trouble Codes.

Read the DTCs.

- Powertrain > Engine and ECT > Trouble Codes

- 50001 234

- Result:

Result Proceed to Only DTC P1603 and/or P1605 is output A DTCs other than P1603 and/or P1605 are output B

- HINT:

-

If any DTCs other than P1603 or P1605 are output, troubleshoot those DTCs first.

A

B

Connect the GTS to the DLC3.

Turn the ignition switch to ON.

Turn the GTS on.

Using the GTS, confirm the vehicle conditions recorded in the freeze frame data which were present when the DTC was stored.

Click hereEngine / Hybrid System>2NZ-FE ENGINE CONTROL>SFI SYSTEM>FREEZE FRAME DATA

- OK:

Immobiliser Fuel Cut is OFF.

- Result:

Result Proceed to NG A OK B

A

B

Connect the GTS to the DLC3.

Start the engine.

Idle the engine.

Turn the GTS on.

Enter the following menus: Powertrain / Engine and ECT / Data List / Immobiliser Communication and Immobiliser Fuel Cut.

- Powertrain > Engine and ECT > Data List

-

Tester Display Immobiliser Communication Immobiliser Fuel Cut - 50003 234 199,505

Check the Data List indication.

- OK:

Data List Item GTS Display Immobiliser Communication ON Immobiliser Fuel Cut OFF

- Result:

Proceed to OK NG

OK

NG

Connect the GTS to the DLC3.

Turn the ignition switch to ON.

Turn the GTS on.

Using the GTS, confirm the vehicle conditions recorded in the freeze frame data which were present when the DTC was stored.

Click hereEngine / Hybrid System>2NZ-FE ENGINE CONTROL>SFI SYSTEM>FREEZE FRAME DATA

- Result:

Problem Symptom Freeze Frame Data Item for DTC P1605 Suspected Area Proceed to Closed Throttle Position SW Engine Speed Total of Short FT #1 and Long FT #1 When idling or decelerating, engine speed slowly decreases and engine stalls All 5 sets of freeze frame data are ON Decreases slowly*1 All 5 sets of freeze frame data are 15% or more*2 ·Air suction

·Sensor malfunction (value from sensor too lean)

·Fuel supply problem

A At least 1 of the 5 sets of freeze frame data is -15% or less*3 Sensor malfunction (value from sensor too rich) B All 5 sets of freeze frame data are from -15% to 15% ·Intake air volume insufficient

·Ignition timing incorrect

C When idling or decelerating, engine speed rapidly decreases and engine stalls Decreases rapidly*1 - ·Injection stoppage, ignition stoppage

·Load from external parts

D When accelerating or driving at constant speed and engine stalls*4 At least one is OFF - - ·Sensor malfunction

·Injection stoppage, ignition stoppage

·Fuel supply problem

E

- HINT:

- ·

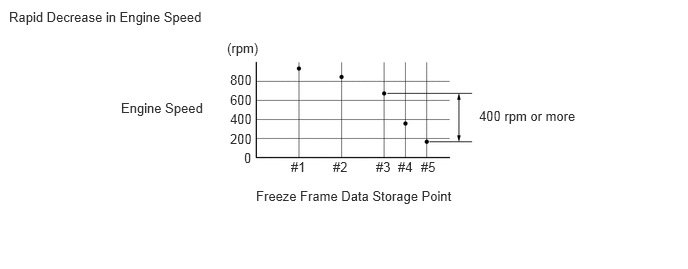

*1: A rapid decrease in engine speed may have been caused by an electrical malfunction in the shared wiring of all or multiple cylinders, an increase in load from external parts, etc. The engine speed is considered to have decreased rapidly if either of the following conditions applies.

Otherwise, the engine speed is considered to have decreased slowly.

(a) In the freeze frame data, the decrease in engine speed from #3 to #5 is 400 rpm or higher.

(b) In the freeze frame data, the engine speed at #5 is 120 rpm or less.

·If the vehicle speed is 20 km/h (12 mph) or less and the difference between the Engine Speed and SPD (NT) is 100 rpm or less, inspect the automatic transaxle. (Depending on the rate of vehicle deceleration, the engine speed may have decreased due to the automatic transaxle lock-up release being late.) (for A/T models)

·*2: When a DTC is stored, feedback compensation increases because the air fuel ratio is determined to be lean.

·*3: When a DTC is stored, feedback compensation decreases because the air fuel ratio is determined to be rich.

·*4: This item should be checked when DTC P1603 is output and is not necessary to check when only P1605 is output.

A

B

C

D

E

Check for air leakage in the intake system [vacuum hose disconnection, cracks, damaged gaskets, etc.].

Click hereEngine / Hybrid System>2NZ-FE INTAKE / EXHAUST>INTAKE SYSTEM>ON-VEHICLE INSPECTION

- HINT:

- ·

If the accelerator pedal is released after racing the engine, the inspection is easier to perform because the vacuum inside the intake pipes increases and the air suction noise becomes louder.

·If Short FT #1 and Long FT #1 are largely different from the normal values when idling (the intake air volume is small) and almost the same as the normal values when racing the engine (the intake air volume is high), air leakage may be present.

- OK:

No leaks in intake system.

- Result:

Proceed to OK NG

OK

NG

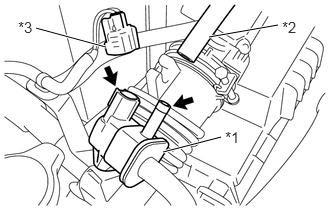

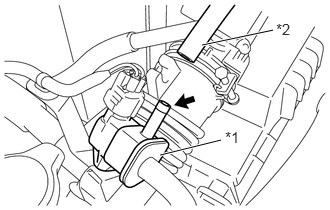

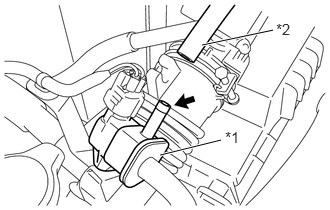

| *1 | Purge VSV |

| *2 | Fuel Vapor Feed Hose (to Canister) |

| *3 | Connector |

Disconnect the fuel vapor feed hose (on the canister side) of the purge VSV.

Start the engine.

Idle the engine.

Disconnect the purge VSV connector.

Check if air flows through the purge VSV.

- OK:

Air does not flow.

- HINT:

-

When this inspection is performed, the MIL may illuminate. After finishing the inspection, check and clear the DTC.

- Result:

Proceed to OK NG

OK

NG

Connect the GTS to the DLC3.

Turn the ignition switch to ON.

Turn the GTS on.

Using the GTS, confirm the vehicle conditions recorded in the freeze frame data which were present when the DTC was stored.

Click hereEngine / Hybrid System>2NZ-FE ENGINE CONTROL>SFI SYSTEM>FREEZE FRAME DATA

- Result:

Freeze Frame Data Item for DTC P1605 Result Suspected Area Proceed to Stop Light Switch At least 1 of the 5 sets of freeze frame data is ON Air suction from brake booster assembly A All 5 sets of freeze frame data are OFF - B

A

B

Connect the GTS to the DLC3.

Turn the ignition switch to ON.

Turn the GTS on.

Start the engine and warm it up until the engine coolant temperature stabilizes.

- HINT:

-

The A/C and all accessory switches should be off.

Idle the engine.

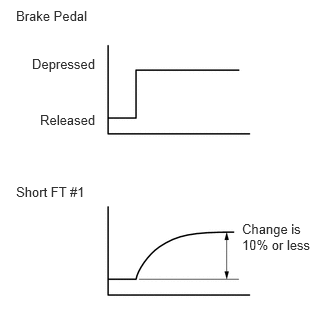

Using the GTS, read the value of Short FT #1 in the Data List while depressing the brake pedal.

- Powertrain > Engine and ECT > Data List

-

Tester Display Short FT #1 - 50003 234 25

- Standard:

Short FT #1 changes by 10% or less.

- HINT:

-

When air leakage from the brake booster assembly is present, the feedback compensation increases because the air fuel ratio becomes lean.

- Result:

Proceed to OK NG

OK

NG

Connect the GTS to the DLC3.

Start the engine and warm it up until the engine coolant temperature stabilizes.

- HINT:

-

The A/C and all accessory switches should be off.

Idle the engine.

Turn the GTS on.

Using the GTS, read the value of Short FT #1 and Long FT #1 in the Data List.

- Powertrain > Engine and ECT > Data List

-

Tester Display Short FT #1 Long FT #1 - 50003 234 25,26

- Standard:

Data List Condition Specified Condition Short FT #1 + Long FT #1 The conditions of the vehicle are matched to those present when the problem occurs -15 to 15%

- Result:

Proceed to OK NG

OK

NG

Perform ignition system On-vehicle Inspection.

Click hereEngine / Hybrid System>2NZ-FE ENGINE CONTROL>IGNITION SYSTEM>ON-VEHICLE INSPECTION

- Result:

Proceed to OK NG

OK

NG

Connect the GTS to the DLC3.

Turn the ignition switch to ON.

Turn the GTS on.

Using the GTS, confirm the vehicle conditions recorded in the freeze frame data which were present when the DTC was stored.

Click hereEngine / Hybrid System>2NZ-FE ENGINE CONTROL>SFI SYSTEM>FREEZE FRAME DATA

- Result:

Freeze Frame Data Item for DTC P1605 Result Suspected Area Proceed to Calculate Load Below 90% of the current value of the vehicle*1 Mass air flow meter sub-assembly A O2S B1S1 Below 0.45 V*2 ·Heated oxygen sensor

·Wire harness or connector

B

- HINT:

- ·

*1: If the mass air flow meter sub-assembly is malfunctioning and incorrectly measures the intake air volume to be less than the actual volume, the freeze frame data will show a low engine load value.

·*2: If the heated oxygen sensor is malfunctioning and constantly outputs a value indicating the air fuel ratio is lean, the actual air fuel ratio will become rich and the engine may stall.

A

B

Remove the mass air flow meter sub-assembly.

Click hereEngine / Hybrid System>2NZ-FE ENGINE CONTROL>MASS AIR FLOW METER>REMOVAL

Check for foreign matter in the air flow passage of the mass air flow meter sub-assembly.

- Result:

Result Proceed to Visible foreign matter is not present A Visible foreign matter is present B

A

B

Check the harnesses and connectors, referring to DTC P0100 inspection procedure.

Click hereEngine / Hybrid System>2NZ-FE ENGINE CONTROL>SFI SYSTEM>P0100

- HINT:

- ·

Jiggle the wire harness and connector to increase the likelihood of detecting malfunctions that do not always occur.

·Make sure there is not an excessive amount of force applied to the wire harness.

- Result:

Proceed to OK NG

OK

NG

Connect the GTS to the DLC3.

Turn the ignition switch to ON.

Turn the GTS on.

Start the engine and warm it up until the engine coolant temperature stabilizes.

- HINT:

-

The A/C and all accessory switches should be off.

Idle the engine.

Using the GTS, read the value of Calculate Load in the Data List.

- Powertrain > Engine and ECT > Data List

-

Tester Display Calculate Load - 50003 234 1

- Standard:

Data List Specified Condition Calculate Load 90 to 110% of the normal value of the vehicle

- Result:

Result Proceed to Abnormal A Normal B

A

B

Connect the GTS to the DLC3.

Start the engine, turn off all accessory switches and warm up the engine until the engine coolant temperature stabilizes.

- HINT:

-

The A/C and all accessory switches should be off.

Idle the engine.

Turn the GTS on.

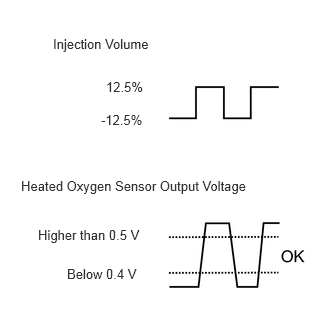

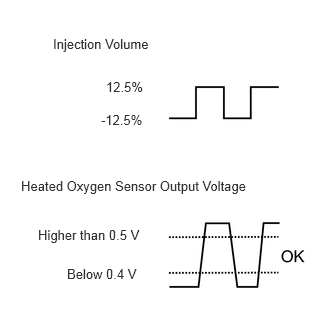

Enter the following menus: Powertrain / Engine and ECT / Active Test / Control the Injection Volume for A/F Sensor / O2S B1S1.

- Powertrain > Engine and ECT > Active Test

-

Active Test Display Control the Injection Volume for A/F Sensor -

Data List Display O2S B1S1 - 50004 234 2 42

Read the output voltage from the heated oxygen sensor when increasing and decreasing the fuel injection volume.

- Standard:

GTS Display Specified Condition Control the Injection Volume for A/F Sensor (12.5%) Heated oxygen sensor output voltage is higher than 0.5 V Control the Injection Volume for A/F Sensor (-12.5%) Heated oxygen sensor output voltage is below 0.4 V

- Result:

Result Proceed to Abnormal A Normal B

- NOTICE:

-

The heated oxygen sensor has an output delay of a few seconds.

A

B

Check the harness and connections, referring to DTC P0031 inspection procedure.

Click hereEngine / Hybrid System>2NZ-FE ENGINE CONTROL>SFI SYSTEM>P0031

- HINT:

- ·

Jiggle the wire harness and connector to increase the likelihood of detecting malfunction that do not always occur.

·Make sure there is not an excessive amount of force applied to the wire harness.

- Result:

Proceed to OK NG

OK

NG

Check the harness and connections, referring to DTC P0134 inspection procedure.

Click hereEngine / Hybrid System>2NZ-FE ENGINE CONTROL>SFI SYSTEM>P0134

- HINT:

- ·

Jiggle the wire harness and connector to increase the likelihood of detecting malfunction that do not always occur.

·Make sure there is not an excessive amount of force applied to the wire harness.

- Result:

Proceed to OK NG

OK

NG

Connect the GTS to the DLC3.

Turn the ignition switch to ON.

Turn the GTS on.

Using the GTS, confirm the vehicle conditions recorded in the freeze frame data which were present when the DTC was stored.

Click hereEngine / Hybrid System>2NZ-FE ENGINE CONTROL>SFI SYSTEM>FREEZE FRAME DATA

- Result:

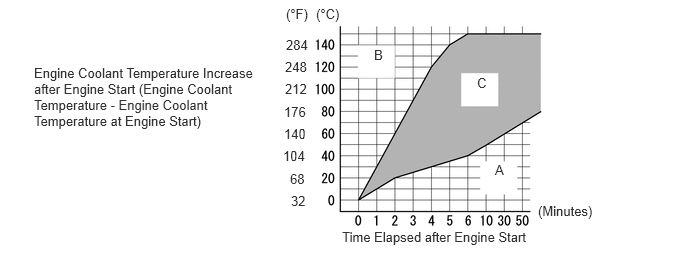

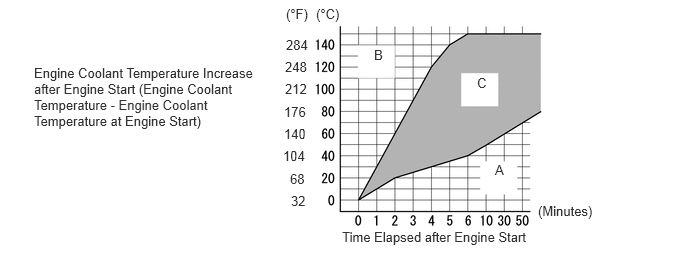

Freeze Frame Data Item for DTC P1605 Result Proceed to Initial Engine Coolant Temp, Ambient Temp for A/C, Initial Intake Air Temp Difference in temperature between each item is less than 10°C (18°F)*1 A Difference in temperature between each item is 10°C (18°F) or higher*2 B

- HINT:

- ·

*1: A long time had elapsed after stopping the engine.

·*2: A long time had not elapsed after stopping the engine.

A

B

Connect the GTS to the DLC3.

Turn the ignition switch to ON.

Turn the GTS on.

Using the GTS, confirm the vehicle conditions recorded in the freeze frame data which were present when the DTC was stored.

Click hereEngine / Hybrid System>2NZ-FE ENGINE CONTROL>SFI SYSTEM>FREEZE FRAME DATA

- Result:

Freeze Frame Data Item for DTC P1605 Result Suspected Area Proceed to Initial Engine Coolant Temp, Coolant Temp, Engine Run Time Range A ·Engine coolant temperature sensor

·Thermostat

A Range B Engine coolant temperature sensor B Range C - C

- HINT:

-

This step is not directly related to engine stall.

A

B

C

Inspect the thermostat.

Click hereEngine / Hybrid System>2NZ-FE COOLING>THERMOSTAT>INSPECTION

- Result:

Result Proceed to Abnormal A Normal B

A

B

Connect the GTS to the DLC3.

Turn the ignition switch to ON.

Turn the GTS on.

Using the GTS, confirm the vehicle conditions recorded in the freeze frame data which were present when the DTC was stored.

Click hereEngine / Hybrid System>2NZ-FE ENGINE CONTROL>SFI SYSTEM>FREEZE FRAME DATA

- Result:

Freeze Frame Data Item for DTC P1605 Result Suspected Area Proceed to Coolant Temp 120°C (248°F) or higher Engine coolant temperature sensor A Engine coolant temperature is lower than ambient temperature* by 15°C (27°F) or higher Engine coolant temperature sensor Values are other than above - B

- HINT:

-

*: Use an actual ambient temperature estimated from the Initial Intake Air, Ambient Temp for A/C, and (if possible) the weather when the DTC was detected.

A

B

Inspect the engine coolant temperature sensor.

Click hereEngine / Hybrid System>2NZ-FE ENGINE CONTROL>ENGINE COOLANT TEMPERATURE SENSOR>INSPECTION

- Result:

Proceed to OK NG

OK

NG

Disconnect the engine coolant temperature sensor connector.

Disconnect the ECM connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection Condition Specified Condition B4-2 - B56-97 (THW) Always Below 1 Ω B4-1 - B56-96 (ETHW) Always Below 1 Ω B4-2 or B56-97 (THW) - Body ground Always 10 kΩ or higher

- HINT:

- ·

Jiggle the wire harness and connector to increase the likelihood of detecting malfunctions that do not always occur.

·Make sure there is not an excessive amount of force applied to the wire harness.

- Result:

Proceed to OK NG

OK

NG

Connect the GTS to the DLC3.

Turn the ignition switch to ON.

Turn the GTS on.

Using the GTS, confirm the vehicle conditions recorded in the freeze frame data which were present when the DTC was stored.

Click hereEngine / Hybrid System>2NZ-FE ENGINE CONTROL>SFI SYSTEM>FREEZE FRAME DATA

- Result:

Freeze Frame Data Item for DTC P1605 Result Suspected Area Proceed to EVAP (Purge) VSV At least 1 of the 5 sets of freeze frame data is not 0% Purge VSV A All 5 sets of freeze frame data are 0% - B

- HINT:

-

If the purge VSV is stuck closed, air fuel ratio compensation by the purge VSV is incorrectly adjusted, and then the air fuel ratio becomes lean and the engine may stall.

A

B

| *1 | Purge VSV |

| *2 | Fuel Vapor Feed Hose (to Canister) |

Disconnect the fuel vapor feed hose (on the canister side) of the purge VSV.

Connect the GTS to the DLC3.

Turn the ignition switch to ON.

Turn the GTS on.

Start the engine.

Enter the following menus: Powertrain / Engine and ECT / Active Test / Activate the VSV for Evap Control.

- Powertrain > Engine and ECT > Active Test

-

Tester Display Activate the VSV for Evap Control - 50004 234 6

When purge VSV is operated using the GTS, check whether the port of the purge VSV applies suction your finger.

- OK:

GTS Operation Specified Condition ON Purge VSV port applies suction to finger OFF Purge VSV port applies no suction to finger

- Result:

Result Proceed to NG A OK B

- HINT:

-

Jiggle the wire harness and connector to increase the likelihood of detecting malfunctions that do not always occur.

A

B

Inspect the purge VSV.

Click hereEngine / Hybrid System>2NZ-FE EMISSION CONTROL>PURGE VALVE>INSPECTION

- Result:

Proceed to OK NG

OK

NG

Check the harness and connectors, referring to DTC P0443 inspection procedure.

Click hereEngine / Hybrid System>2NZ-FE ENGINE CONTROL>SFI SYSTEM>P0443

- HINT:

- ·

Jiggle the wire harness and connector to increase the likelihood of detecting malfunctions that do not always occur.

·Make sure there is not an excessive amount of force applied to the wire harness.

- Result:

Proceed to OK NG

OK

NG

Check the harness and connectors, referring to DTC P0443 inspection procedure.

Click hereEngine / Hybrid System>2NZ-FE ENGINE CONTROL>SFI SYSTEM>P0443

- HINT:

- ·

Jiggle the wire harness and connector to increase the likelihood of detecting malfunctions that do not always occur.

·Make sure there is not an excessive amount of force applied to the wire harness.

- Result:

Proceed to OK NG

OK

NG

Connect the GTS to the DLC3.

Turn the ignition switch to ON.

Turn the GTS on.

Clear the DTCs.

- Powertrain > Engine and ECT > Clear DTCs

- 50002 234

- Result:

Proceed to NEXT

NEXT

Connect the GTS to the DLC3.

Start the engine and warm it up until the engine coolant temperature stabilizes.

- HINT:

-

The A/C and all accessory switches should be off.

Idle the engine for 15 minutes or more.

Turn the GTS on.

Using the GTS, read the value of EVAP (Purge) VSV in the Data List.

- Powertrain > Engine and ECT > Data List

-

Tester Display EVAP (Purge) VSV - 50003 234 31

- Standard:

Data List Specified Condition EVAP (Purge) VSV Value other than 0% is displayed

- Result:

Result Proceed to Abnormal A Normal B

A

B

| *1 | Purge VSV |

| *2 | Fuel Vapor Feed Hose (to Canister) |

Disconnect the fuel vapor feed hose (on the canister side) of the purge VSV.

Connect the GTS to the DLC3.

Turn the ignition switch to ON.

Turn the GTS on.

Start the engine.

Enter the following menus: Powertrain / Engine and ECT / Active Test / Activate the VSV for Evap Control.

- Powertrain > Engine and ECT > Active Test

-

Tester Display Activate the VSV for Evap Control - 50004 234 6

When purge VSV is operated using the GTS, check whether the port of the purge VSV applies suction your finger.

- OK:

GTS Operation Specified Condition ON Purge VSV port applies suction to finger OFF Purge VSV port applies no suction to finger

- Result:

Result Proceed to NG A OK B

- HINT:

-

Jiggle the wire harness and connector to increase the likelihood of detecting malfunctions that do not always occur.

A

B

Check the ECM connector connection condition.

- HINT:

- ·

Jiggle the wire harness and connector to increase the likelihood of detecting malfunctions that do not always occur.

·Make sure there is not an excessive amount of force applied to the wire harness.

- Result:

Proceed to OK NG

OK

NG

Connect the GTS to the DLC3.

Turn the ignition switch to ON.

Turn the GTS on.

Enter the following menus: Powertrain / Engine and ECT / Active Test / Control the Fuel Pump / Speed.

- Powertrain > Engine and ECT > Active Test

-

Tester Display Control the Fuel Pump / Speed - 50004 234 5

When performing the Active Test, check for an operating sound from the fuel pump.

- OK:

GTS Operation Specified Condition ON Operating sound heard OFF Operating sound not heard

- Result:

Result Proceed to NG A OK B

- HINT:

- ·

Jiggle the wire harness and connector to increase the likelihood of detecting malfunctions that do not always occur.

·While performing the Active Test, make sure that there is no fuel leakage from the pipes, no signs that fuel has leaked, and no fuel smell.

·If the fuel pump operating noise is abnormal, proceed to step 34.

A

B

Inspect the fuel pump.

Click hereEngine / Hybrid System>2NZ-FE FUEL>FUEL PUMP>INSPECTION

- Result:

Proceed to OK NG

OK

NG

Check the fuel system.

Check the fuel pump operation.

Check the fuel leaks.

Check the fuel pressure.

Perform the Active Test [Control the All Cylinders Fuel Cut].

- HINT:

-

For the fuel system On-vehicle Inspection, refer to the following procedures.

-

Click hereEngine / Hybrid System>2NZ-FE FUEL>FUEL SYSTEM>ON-VEHICLE INSPECTION

- Result:

Result Proceed to Abnormal A Normal B

A

B

Check for foreign matter such as iron particles around the fuel pump (fuel pump, fuel pump filter and inside the fuel tank), and for signs that the fuel pump was stuck.

- Result:

Result Proceed to There is no foreign matter and no signs that fuel pump was stuck A There is foreign matter or signs that fuel pump was stuck B

- HINT:

-

If there is foreign matter such as iron particles on the fuel pump, fuel filter or fuel tank, remove the foreign matter.

A

B

Check the fuel system.

Check the fuel pump operation.

Check the fuel leaks.

Check the fuel pressure.

Perform the Active Test [Control the All Cylinders Fuel Cut].

- HINT:

-

For the fuel system On-vehicle Inspection, refer to the following procedures.

-

Click hereEngine / Hybrid System>2NZ-FE FUEL>FUEL SYSTEM>ON-VEHICLE INSPECTION

- Result:

Proceed to OK NG

OK

NG

Perform ignition system On-vehicle Inspection.

Click hereEngine / Hybrid System>2NZ-FE ENGINE CONTROL>IGNITION SYSTEM>ON-VEHICLE INSPECTION

- Result:

Proceed to OK NG

OK

NG

Connect the GTS to the DLC3.

Turn the ignition switch to ON.

Turn the GTS on.

Using the GTS, confirm the vehicle conditions recorded in the freeze frame data which were present when the DTC was stored.

Click hereEngine / Hybrid System>2NZ-FE ENGINE CONTROL>SFI SYSTEM>FREEZE FRAME DATA

- Result:

Freeze Frame Data Item for DTC P1605 Result Suspected Area Proceed to Calculate Load 110% or more of the current value of the vehicle*1 Mass air flow meter sub-assembly A O2S B1S1 0.45 V or higher*2 ·Heated oxygen sensor

·Harness or connector

B Both freeze frame data items listed above Values are other than above - C

- HINT:

- ·

*1: If the mass air flow meter sub-assembly is malfunctioning and incorrectly measures the intake air volume to be higher than the actual volume of air flowing through the intake manifold, the freeze frame data will show a high engine load value.

·*2: As the heated oxygen sensor output is low before the sensor warms up, the value at that time cannot be used for diagnosis. If the heated oxygen sensor is malfunctioning and constantly outputs a value indicating the air fuel ratio is rich, the actual air fuel ratio will become lean and the engine may stall.

A

B

C

Remove the mass air flow meter sub-assembly.

Click hereEngine / Hybrid System>2NZ-FE ENGINE CONTROL>MASS AIR FLOW METER>REMOVAL

Check for foreign matter in the air flow passage of the mass air flow meter sub-assembly.

- Result:

Result Proceed to Visible foreign matter is not present A Visible foreign matter is present B

A

B

Check the harnesses and connectors, referring to DTC P0100 inspection procedure.

Click hereEngine / Hybrid System>2NZ-FE ENGINE CONTROL>SFI SYSTEM>P0100

- HINT:

- ·

Jiggle the wire harness and connector to increase the likelihood of detecting malfunctions that do not always occur.

·Make sure there is not an excessive amount of force applied to the wire harness.

- Result:

Proceed to OK NG

OK

NG

Connect the GTS to the DLC3.

Turn the ignition switch to ON.

Turn the GTS on.

Start the engine and warm it up until the engine coolant temperature stabilizes.

- HINT:

-

The A/C and all accessory switches should be off.

Idle the engine.

Using the GTS, read the value of Calculate Load in the Data List.

- Powertrain > Engine and ECT > Data List

-

Tester Display Calculate Load - 50003 234 1

- Standard:

Data List Specified Condition Calculate Load 90 to 110% of the normal value of the vehicle

- Result:

Proceed to OK NG

OK

NG

Connect the GTS to the DLC3.

Start the engine, turn off all accessory switches and warm up the engine until the engine coolant temperature stabilizes.

- HINT:

-

The A/C and all accessory switches should be off.

Idle the engine.

Turn the GTS on.

Enter the following menus: Powertrain / Engine and ECT / Active Test / Control the Injection Volume for A/F Sensor / O2S B1S1.

- Powertrain > Engine and ECT > Active Test

-

Active Test Display Control the Injection Volume for A/F Sensor -

Data List Display O2S B1S1 - 50004 234 2 42

Read the output voltage from the heated oxygen sensor when increasing and decreasing the fuel injection volume.

- Standard:

GTS Display Specified Condition Control the Injection Volume for A/F Sensor (12.5%) Heated oxygen sensor output voltage is higher than 0.5 V Control the Injection Volume for A/F Sensor (-12.5%) Heated oxygen sensor output voltage is below 0.4 V

- Result:

Result Proceed to Abnormal A Normal B

- NOTICE:

-

The heated oxygen sensor has an output delay of a few seconds.

A

B

Check the harness and connections, referring to DTC P0031 inspection procedure.

Click hereEngine / Hybrid System>2NZ-FE ENGINE CONTROL>SFI SYSTEM>P0031

- HINT:

- ·

Jiggle the wire harness and connector to increase the likelihood of detecting malfunction that do not always occur.

·Make sure there is not an excessive amount of force applied to the wire harness.

- Result:

Result OK NG

OK

NG

Check the harness and connections, referring to DTC P0134 inspection procedure.

Click hereEngine / Hybrid System>2NZ-FE ENGINE CONTROL>SFI SYSTEM>P0134

- HINT:

- ·

Jiggle the wire harness and connector to increase the likelihood of detecting malfunction that do not always occur.

·Make sure there is not an excessive amount of force applied to the wire harness.

- Result:

Proceed to OK NG

OK

NG

Connect the GTS to the DLC3.

Turn the ignition switch to ON.

Turn the GTS on.

Using the GTS, confirm the vehicle conditions recorded in the freeze frame data which were present when the DTC was stored.

Click hereEngine / Hybrid System>2NZ-FE ENGINE CONTROL>SFI SYSTEM>FREEZE FRAME DATA

- Result:

Freeze Frame Data Item for DTC P1605 Result Proceed to Initial Engine Coolant Temp, Ambient Temp for A/C, Initial Intake Air Temp Difference in temperature between each item is less than 10°C (18°F)*1 A Difference in temperature between each item is 10°C (18°F) or higher*2 B

- HINT:

- ·

*1: A long time had elapsed after stopping the engine.

·*2: A long time had not elapsed after stopping the engine.

A

B

Connect the GTS to the DLC3.

Turn the ignition switch to ON.

Turn the GTS on.

Using the GTS, confirm the vehicle conditions recorded in the freeze frame data which were present when the DTC was stored.

Click hereEngine / Hybrid System>2NZ-FE ENGINE CONTROL>SFI SYSTEM>FREEZE FRAME DATA

- Result:

Freeze Frame Data Item for DTC P1605 Result Suspected Area Proceed to Initial Engine Coolant Temp, Coolant Temp, Engine Run Time Range A ·Engine coolant temperature sensor

·Thermostat

A Range B Engine coolant temperature sensor B Range C - C

- HINT:

-

This step is not directly related to engine stall.

A

B

C

Inspect the thermostat.

Click hereEngine / Hybrid System>2NZ-FE COOLING>THERMOSTAT>INSPECTION

- Result:

Result Proceed to Abnormal A Normal B

- HINT:

-

This step is not directly related to engine stall.

A

B

Connect the GTS to the DLC3.

Turn the ignition switch to ON.

Turn the GTS on.

Using the GTS, confirm the vehicle conditions recorded in the freeze frame data which were present when the DTC was stored.

Click hereEngine / Hybrid System>2NZ-FE ENGINE CONTROL>SFI SYSTEM>FREEZE FRAME DATA

- Result:

Freeze Frame Data Item for DTC P1605 Result Suspected Area Proceed to Coolant Temp 120°C (248°F) or higher Engine coolant temperature sensor A Engine coolant temperature is lower than ambient temperature* by 15°C (27°F) or higher Engine coolant temperature sensor Values are other than above - B

- HINT:

-

*: Use an actual ambient temperature estimated from the Initial Intake Air, Ambient Temp for A/C, and (if possible) the weather when the DTC was detected.

A

B

Inspect the engine coolant temperature sensor.

Click hereEngine / Hybrid System>2NZ-FE ENGINE CONTROL>ENGINE COOLANT TEMPERATURE SENSOR>INSPECTION

- Result:

Proceed to OK NG

OK

NG

Disconnect the engine coolant temperature sensor connector.

Disconnect the ECM connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection Condition Specified Condition B4-2 - B56-97 (THW) Always Below 1 Ω B4-1 - B56-96 (ETHW) Always Below 1 Ω B4-2 or B56-97 (THW) - Body ground Always 10 kΩ or higher

- HINT:

- ·

Jiggle the wire harness and connector to increase the likelihood of detecting malfunctions that do not always occur.

·Make sure there is not an excessive amount of force applied to the wire harness.

- Result:

Proceed to OK NG

OK

NG

Connect the GTS to the DLC3.

Turn the ignition switch to ON.

Turn the GTS on.

Clear the DTCs.

- Powertrain > Engine and ECT > Clear DTCs

- 50002 234

- Result:

Proceed to NEXT

NEXT

Perform ignition system On-vehicle Inspection.

Click hereEngine / Hybrid System>2NZ-FE ENGINE CONTROL>IGNITION SYSTEM>ON-VEHICLE INSPECTION

- Result:

Proceed to OK NG

OK

NG

Connect the GTS to the DLC3.

Turn the ignition switch to ON.

Turn the GTS on.

Using the GTS, confirm the vehicle conditions recorded in the freeze frame data which were present when the DTC was stored.

Click hereEngine / Hybrid System>2NZ-FE ENGINE CONTROL>SFI SYSTEM>FREEZE FRAME DATA

- Result:

Freeze Frame Data Item for DTC P1605 Result Suspected Area Proceed to Total of ISC Learning Value and ISC Feedback Value Below 80% of the current value of the vehicle Intake air volume insufficient A 80% or higher of the current value of the vehicle B

A

B

Check for air leakage in the intake system [vacuum hose disconnection, cracks, damaged gaskets, etc.].

Click hereEngine / Hybrid System>2NZ-FE INTAKE / EXHAUST>INTAKE SYSTEM>ON-VEHICLE INSPECTION

- HINT:

- ·

If the accelerator pedal is released after racing the engine, the inspection is easier to perform because the vacuum inside the intake pipes increases and the air suction noise becomes louder.

·If Short FT #1 and Long FT #1 are largely different from the normal values when idling (the intake air volume is small) and almost the same as the normal values when racing the engine (the intake air volume is high), air leakage may be present.

- OK:

No leaks in intake system.

- Result:

Proceed to OK NG

OK

NG

Check the intake system.

Inspect the brake booster assembly.

Click hereBrake>BRAKE SYSTEM (OTHER)>BRAKE BOOSTER>INSPECTION

Inspect the mass air flow meter sub-assembly.

Click hereEngine / Hybrid System>2NZ-FE ENGINE CONTROL>MASS AIR FLOW METER>ON-VEHICLE INSPECTION

Check the PCV hose.

Click hereEngine / Hybrid System>2NZ-FE EMISSION CONTROL>PCV VALVE>COMPONENTS

Inspect the PCV valve.

Click hereEngine / Hybrid System>2NZ-FE EMISSION CONTROL>PCV VALVE>INSPECTION

Inspect the purge VSV.

Click hereEngine / Hybrid System>2NZ-FE EMISSION CONTROL>PURGE VALVE>INSPECTION

- Result:

Result Proceed to Abnormal A Normal B

A

B

Perform the Active Test, referring to DTC P0011 inspection procedure.

Click hereEngine / Hybrid System>2NZ-FE ENGINE CONTROL>SFI SYSTEM>P0011

- HINT:

- ·

Jiggle the wire harness and connector to increase the likelihood of detecting malfunctions that do not always occur.

·When the results of the inspection using the Active Test are normal but the valve operating noise is abnormal, check the valve for any signs of problems.

·If the camshaft timing oil control valve assembly is stuck at the advanced side, the valve overlap increases and combustion worsens due to the interval EGR which may cause rough idle or cause the engine to stall.

- Result:

Proceed to OK NG

OK

NG

Check the harnesses and connectors, referring to DTC P0010 inspection procedure.

Click hereEngine / Hybrid System>2NZ-FE ENGINE CONTROL>SFI SYSTEM>P0010

- HINT:

- ·

Jiggle the wire harness and connector to increase the likelihood of detecting malfunctions that do not always occur.

·Make sure there is not an excessive amount of force applied to the wire harness.

- Result:

Proceed to OK NG

OK

NG

Connect the GTS to the DLC3.

Turn the ignition switch to ON.

Turn the GTS on.

Using the GTS, confirm the vehicle conditions recorded in the freeze frame data which were present when the DTC was stored.

Click hereEngine / Hybrid System>2NZ-FE ENGINE CONTROL>SFI SYSTEM>FREEZE FRAME DATA

- Result:

Freeze Frame Data Item for DTC P1605 Suspected Area Proceed to IGN Advance Knock Correct Learn Value Differs from the current value of the vehicle by 10 deg or more Less than 3 deg(CA) ·Engine coolant temperature sensor

·Mass air flow meter sub-assembly

·Knock control sensor

A 3 deg(CA) or more - B Differs from the current value of the vehicle by less than 10 deg - -

A

B

Inspect the engine coolant temperature sensor.

Click hereEngine / Hybrid System>2NZ-FE ENGINE CONTROL>ENGINE COOLANT TEMPERATURE SENSOR>INSPECTION

- Result:

Proceed to OK NG

OK

NG

Disconnect the engine coolant temperature sensor connector.

Disconnect the ECM connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection Condition Specified Condition B4-2 - B56-97 (THW) Always Below 1 Ω B4-1 - B56-96 (ETHW) Always Below 1 Ω B4-2 or B56-97 (THW) - Body ground Always 10 kΩ or higher

- HINT:

- ·

Jiggle the wire harness and connector to increase the likelihood of detecting malfunctions that do not always occur.

·Make sure there is not an excessive amount of force applied to the wire harness.

- Result:

Proceed to OK NG

OK

NG

Inspect the mass air flow meter sub-assembly.

Click hereEngine / Hybrid System>2NZ-FE ENGINE CONTROL>MASS AIR FLOW METER>INSPECTION

- HINT:

-

If the intake air temperature sent to the ECM is higher than the standard due to the mass air flow meter sub-assembly (intake air temperature sensor) malfunctioning, the ignition timing may become delayed.

- Result:

Proceed to OK NG

OK

NG

Connect the GTS to the DLC3.

Start the engine and warm it up until the engine coolant temperature stabilizes.

- HINT:

-

The A/C and all accessory switches should be off.

Turn the GTS on.

Idle the engine.

Enter the following menus: Powertrain / Engine and ECT / Data List / IGN Advance and Knock Correct Learn Value.

- Powertrain > Engine and ECT > Data List

-

Tester Display IGN Advance Knock Correct Learn Value - 50003 234 29,191

Check the Data List indication.

- Result:

Data List Proceed to IGN Advance Knock Correct Learn Value Differs from the current value of the vehicle by 10 deg or more Less than 3 deg(CA) A 3 deg(CA) or more B Differs from the current value of the vehicle by less than 10 deg -

- HINT:

-

If the results of the checks performed in steps 57 to 63 were all normal and the sum of ISC Feedback Value and ISC Learning Value in the Data List is 120% of the normal value or more, check for carbon deposits in the throttle body with motor assembly. If there are carbon deposits, clean them off to finish the troubleshooting procedure.

A

B

Check the harness and connectors, referring to Fuel Injector Circuit inspection procedure.

Click hereEngine / Hybrid System>2NZ-FE ENGINE CONTROL>SFI SYSTEM>Fuel Injector Circuit

- HINT:

- ·

Jiggle the wire harness and connector to increase the likelihood of detecting malfunctions that do not always occur.

·Make sure there is not an excessive amount of force applied to the wire harness.

·A rapid decrease in engine speed may have been caused by a malfunction in all or multiple cylinders. (There may be an electrical malfunction in the wiring shared by all the cylinders.)

- Result:

Proceed to OK NG

OK

NG

Perform ignition system On-vehicle Inspection.

Click hereEngine / Hybrid System>2NZ-FE ENGINE CONTROL>IGNITION SYSTEM>ON-VEHICLE INSPECTION

- Result:

Proceed to OK NG

OK

NG

Connect the GTS to the DLC3.

Turn the ignition switch to ON.

Turn the GTS on.

Using the GTS, confirm the vehicle conditions recorded in the freeze frame data which were present when the DTC was stored.

Click hereEngine / Hybrid System>2NZ-FE ENGINE CONTROL>SFI SYSTEM>FREEZE FRAME DATA

- Result:

Freeze Frame Data Item for DTC P1605 Suspected Area Proceed to A/C Signal Air Conditioner FB Val Power Steering Signal A/C Signal display changes from OFF to ON*1 Value is shown - A/C system A Value is 0 L/s Does not change from OFF - B

*2

C

*3Changes from OFF to ON Power steering system A/C Signal display does not change from OFF*1 - Changes from OFF to ON Does not change from OFF -

- HINT:

- ·

*1: Check not only the ON/OFF state of the air conditioner but also the change in air conditioner load.

·*2: for A/T models

·*3: for M/T models

·The normal value for the ISC learned value is engine displacement (liters) x 0.9.

·Even if the results are normal, the power steering system or A/C system may have been malfunctioning. If there are no problems with other parts, inspect the power steering system or A/C system.

A

B

C

Connect the GTS to the DLC3.

Turn the ignition switch to ON.

Turn the GTS on.

Using the GTS, confirm the vehicle conditions recorded in the freeze frame data which were present when the DTC was stored.

Click hereEngine / Hybrid System>2NZ-FE ENGINE CONTROL>SFI SYSTEM>FREEZE FRAME DATA

- Result:

Freeze Frame Data Item for DTC P1605 Suspected Area Proceed to Electrical Load Signal 1 (2) or Electric Load Feedback Val Electric Load Feedback Val Difference between Engine Speed and SPD (NT) Vehicle Speed Electrical Load Signal 1 (2) display changes from OFF to ON*1, or value displayed for Electric Load Feedback Val increases*1 Value displayed for Electric Load Feedback Val changes - - Electrical load signal circuit C Value displayed for Electric Load Feedback Val does not change At least 1 of the 5 sets of freeze frame data is less than 100 rpm Less than 20 km/h (12 mph) A/T system B 20 km/h (12 mph) or more - A All 5 sets of freeze frame data are 100 rpm or more - - Electrical Load Signal 1 (2) display does not change from OFF, or value displayed for Electric Load Feedback Val does not increase - At least 1 of the 5 sets of freeze frame data is less than 100 rpm Less than 20 km/h (12 mph) A/T system B 20 km/h (12 mph) or more - A All 5 sets of freeze frame data are 100 rpm or more - -

- HINT:

- ·

*1: If the Electrical Load Signal 1 (2) display changes from OFF to ON, or the "Electric Load Feedback Val" increases, it probably is a malfunction due to a change in electrical load. Check the generator and the continuity and connections between the generator and ECM.

·If the vehicle speed is 20 km/h (12 mph) or less and the difference between Engine Speed and SPD (NT) is 100 rpm or less, inspect the automatic transaxle. (Depending on the rate of vehicle deceleration, the engine speed may have decreased due to the automatic transaxle lock-up release being late.)

·The normal value for the ISC learned value is engine displacement (liters) x 0.9.

·Even if the results are normal, the electrical load signal system or automatic transaxle system may have been malfunctioning. If there are no problems with other parts, inspect the electrical load system and/or A/T system.

A

B

C

Connect the GTS to the DLC3.

Turn the ignition switch to ON.

Turn the GTS on.

Using the GTS, confirm the vehicle conditions recorded in the freeze frame data which were present when the DTC was stored.

Click hereEngine / Hybrid System>2NZ-FE ENGINE CONTROL>SFI SYSTEM>FREEZE FRAME DATA

- Result:

Freeze Frame Data Item for DTC P1605 Suspected Area Proceed to Shift SW Status (P Range)

Shift SW Status (N Range)Neutral Position SW Signal P and N position are both OFF in at least one data set ON when shift lever in D or R Park/neutral position switch assembly A OFF when shift lever in D or R A/T system B All 5 sets of freeze frame data are ON - - C

- HINT:

-

Even if the results are normal, the park/neutral position switch assembly or A/T system may have been malfunctioning. If there are no problems with other parts, inspect the park/neutral position switch assembly or automatic transaxle system.

A

Click hereDrivetrain>U441E AUTOMATIC TRANSMISSION / TRANSAXLE>PARK / NEUTRAL POSITION SWITCH>INSPECTION

B

C

Connect the GTS to the DLC3.

Turn the ignition switch to ON.

Turn the GTS on.

Using the GTS, confirm the vehicle conditions recorded in the freeze frame data which were present when the DTC was stored.

Click hereEngine / Hybrid System>2NZ-FE ENGINE CONTROL>SFI SYSTEM>FREEZE FRAME DATA

- Result:

Freeze Frame Data Item for DTC P1605 Suspected Area Proceed to Electrical Load Signal 1 (2) or Electric Load Feedback Val Electric Load Feedback Val Electrical Load Signal 1 (2) display changes from OFF to ON*, or value displayed for Electric Load Feedback Val increases* Value displayed for Electric Load Feedback Val changes Electrical load signal circuit A Value displayed for Electric Load Feedback Val does not change - B Electrical Load Signal 1 (2) display does not change from OFF, or value displayed for Electric Load Feedback Val does not increase - -

- HINT:

- ·

*: If the Electrical Load Signal 1 (2) display changes from OFF to ON, or the "Electric Load Feedback Val" increases, it probably is a malfunction due to a change in electrical load. Check the generator and the continuity and connections between the generator and ECM.

·The normal value for the ISC learned value is engine displacement (liters) x 0.9.

·Even if the results are normal, the electrical load signal system may have been malfunctioning. If there are no problems with other parts, inspect the electrical load system.

A

B

Connect the GTS to the DLC3.

Turn the ignition switch to ON.

Turn the GTS on.

Using the GTS, confirm the vehicle conditions recorded in the freeze frame data which were present when the DTC was stored.

Click hereEngine / Hybrid System>2NZ-FE ENGINE CONTROL>SFI SYSTEM>FREEZE FRAME DATA

- Result:

Freeze Frame Data Item Result Suspected Area Proceed to Throttle Sensor Position, Calculate Load Calculate Load decreases while Throttle Sensor Position increases Mass air flow meter sub-assembly A Calculate Load does not decrease while Throttle Sensor Position increases - B

A

B

Remove the mass air flow meter sub-assembly.

Click hereEngine / Hybrid System>2NZ-FE ENGINE CONTROL>MASS AIR FLOW METER>REMOVAL

Check for foreign matter in the air flow passage of the mass air flow meter sub-assembly.

- Result:

Result Proceed to Visible foreign matter is not present A Visible foreign matter is present B

A

B

Check the harnesses and connectors, referring to DTC P0100 inspection procedure.

Click hereEngine / Hybrid System>2NZ-FE ENGINE CONTROL>SFI SYSTEM>P0100

- HINT:

- ·

Jiggle the wire harness and connector to increase the likelihood of detecting malfunctions that do not always occur.

·Make sure there is not an excessive amount of force applied to the wire harness.

- Result:

Proceed to OK NG

OK

NG

Connect the GTS to the DLC3.

Turn the ignition switch to ON.

Turn the GTS on.

Start the engine and warm it up until the engine coolant temperature stabilizes.

- HINT:

-

The A/C and all accessory switches should be off.

Idle the engine.

Using the GTS, read the value of Calculate Load in the Data List.

- Powertrain > Engine and ECT > Data List

-

Tester Display Calculate Load - 50003 234 1

- Standard:

Data List Specified Condition Calculate Load 90 to 110% of the normal value of the vehicle

- Result:

Proceed to OK NG

OK

NG

Check the harness and connectors, referring to Fuel Injector Circuit inspection procedure.

Click hereEngine / Hybrid System>2NZ-FE ENGINE CONTROL>SFI SYSTEM>Fuel Injector Circuit

- HINT:

- ·

Jiggle the wire harness and connector to increase the likelihood of detecting malfunctions that do not always occur.

·Make sure there is not an excessive amount of force applied to the wire harness.

·A rapid decrease in engine speed may have been caused by a malfunction in all or multiple cylinders. (There may be an electrical malfunction in the wiring shared by all the cylinders.)

- Result:

Proceed to OK NG

OK

NG

Perform ignition system On-vehicle Inspection.

Click hereEngine / Hybrid System>2NZ-FE ENGINE CONTROL>IGNITION SYSTEM>ON-VEHICLE INSPECTION

- Result:

Proceed to OK NG

OK

NG

Connect the GTS to the DLC3.

Turn the ignition switch to ON.

Turn the GTS on.

Enter the following menus: Powertrain / Engine and ECT / Active Test / Control the Fuel Pump / Speed.

- Powertrain > Engine and ECT > Active Test

-

Tester Display Control the Fuel Pump / Speed - 50004 234 5

When performing the Active Test, check for an operating sound from the fuel pump.

- Standard:

GTS Operation Specified Condition ON Operating sound heard OFF Operating sound not heard

- Result:

Result Proceed to Abnormal A Normal B

- HINT:

- ·

Jiggle the wire harness and connector to increase the likelihood of detecting malfunctions that do not always occur.

·While performing the Active Test, make sure that there is no fuel leakage from the pipes, no signs that fuel has leaked, and no fuel smell.

·If the fuel pump operating noise is abnormal, proceed to step 77.

A

B

Inspect the fuel pump.

Click hereEngine / Hybrid System>2NZ-FE FUEL>FUEL PUMP>INSPECTION

- Result:

Proceed to OK NG

OK

NG

Check the fuel system.

Check the fuel pump operation.

Check the fuel leaks.

Check the fuel pressure.

Perform the Active Test [Control the All Cylinder Fuel Cut].

- HINT:

-

For the fuel system On-vehicle Inspection, refer to the following procedures.

-

Click hereEngine / Hybrid System>2NZ-FE FUEL>FUEL SYSTEM>ON-VEHICLE INSPECTION

- Result:

Result Proceed to Abnormal A Normal B

A

B

Check for foreign matter such as iron particles around the fuel pump (fuel pump, fuel pump filter and inside the fuel tank), and for signs that the fuel pump was stuck.

- Result:

Result Proceed to There is no foreign matter and no signs that fuel pump was stuck A There is foreign matter or signs that fuel pump was stuck B

- HINT:

-

If there is foreign matter such as iron particles on the fuel pump, fuel filter or fuel tank, remove the foreign matter.

A

B

Check the fuel system.

Check the fuel pump operation.

Check the fuel leaks.

Check the fuel pressure.

Perform the Active Test [Control the All Cylinder Fuel Cut].

- HINT:

-

For the fuel system On-vehicle Inspection, refer to the following procedures.

-

Click hereEngine / Hybrid System>2NZ-FE FUEL>FUEL SYSTEM>ON-VEHICLE INSPECTION

- Result:

Proceed to OK NG

OK

NG