THEFT DETERRENT / KEYLESS ENTRY SMART ENTRY AND START SYSTEM(for Start Function) Engine does not Start

DESCRIPTION

When the key is in the vehicle and the engine switch is pressed, the certification ECU (smart key ECU assembly) receives a signal and changes the power source mode. In addition, when the shift lever is in P*1 and the brake pedal*1 or clutch pedal*2 is depressed, the engine can be started by pressing the engine switch.

*1: except Manual Transaxle

*2: for Manual Transaxle

| Problem Symptom | Data List Item | Active Test Item |

|---|---|---|

| Engine does not start | Power Source Control

·

Stop Light Switch1 ·

Steering Unlock Switch ·

Power Supply Condition ·

IG1 Relay Monitor(Inside) ·

IG2 Relay Monitor(Inside) ·

IG1 Relay Monitor(Outside) ·

IG2 Relay Monitor(Outside) ·

Latch Circuit ·

Shift P Signal ·

Neutral SW/ Clutch SW ·

Starter Request Signal Entry&Start

·

S Code Check ·

L Code Check ·

Engine Start Request ·

Immobiliser Starting Control

·

Ignition ·

Starter SW ·

Shift Position P or N |

- |

- HINT:

-

If the brake pedal is repeatedly depressed while the engine is stopped, the brake booster pressure is released and the force required to depress the brake pedal to illuminate the stop lights increases.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

- NOTICE:

- ·

When using the GTS with the engine switch off, connect the GTS to the DLC3 and turn a courtesy light switch on and off at intervals of 1.5 seconds or less until communication between the GTS and the vehicle begins. Then select Model Code "KEY REGIST" under manual mode and enter the following menus: Body Electrical / Entry&Start(CAN). While using the GTS, periodically turn a courtesy light switch on and off at intervals of 1.5 seconds or less to maintain communication between the GTS and the vehicle.

·The smart entry and start system (for Start Function) uses the LIN communication system and CAN communication system. Inspect the communication function by following How to Proceed with Troubleshooting. Troubleshoot the smart entry and start system (for Start Function) after confirming that the communication systems are functioning properly.

·If the smart entry and start system is disabled through the customize function, enable the system before performing troubleshooting.

·Before replacing the certification ECU (smart key ECU assembly), ID code box (immobiliser code ECU) or steering lock ECU (steering lock actuator assembly), refer to smart entry and start system (for Start Function) Precaution.

·Inspect the fuses of circuits related to this system before performing the following procedure.

·If the steering lock ECU (steering lock actuator assembly) is replaced, be sure to confirm that the steering is unlocked by turning the steering to the left and right before starting the engine. If the steering is locked for any reason, open and close a door with the engine switch off, and then unlock the steering by pressing the engine switch. This prevents the engine from starting while the steering is locked.

·After completing repairs, confirm that the problem does not occur.

- HINT:

- ·

When the certification ECU (smart key ECU assembly) is replaced with a new one and the cable is connected to the negative (-) battery terminal, the power source mode changes to on (IG).

·When the battery cable is disconnected and reconnected, the power source returns to the mode it was in before the battery cable was disconnected.

PROCEDURE

Measure the battery voltage.

- Standard Voltage:

11 to 14 V

- HINT:

- ·

It may be possible to tell whether the vehicle battery is discharged by operating the horn.

·If the battery voltage is less than 11 V, recharge or replace it.

- Result:

Proceed to NEXT

NEXT

Using the GTS, confirm the output of DTCs for all systems.

- NOTICE:

-

Make sure that no DTCs are output. If any DTCs are output, proceed to Diagnostic Trouble Code Chart.

- OK:

No DTCs are output.

- Result:

Proceed to OK NG

OK

NG

If the problem occurs in certain locations or times of day, the possibility of wave interference is high.

- HINT:

-

Whether or not the problem is due to wave interference can be checked by holding the electrical key transmitter sub-assembly near the door control with receiver ECU assembly (RF band).

- OK:

Engine starts.

- Result:

Proceed to OK NG

OK

NG

Get into the vehicle while carrying an electrical key transmitter sub-assembly.

Move the shift lever to P.*1

With the brake pedal released, check that pressing the engine switch causes the power source mode to change.*1

With the clutch pedal released, check that pressing the engine switch causes the power source mode to change.*2

*1: except Manual Transaxle

*2: for Manual Transaxle

- Result:

Result Proceed to Power source mode changes : Off → on (ACC) → on (IG) → off A Power source mode does not change to on (ACC) or on (IG) B Power source mode changes to on (IG) but not to on (ACC) C Power source mode changes to on (ACC) but not to on (IG) D

A

B

C

D

Get into the vehicle while carrying an electrical key transmitter sub-assembly.

Move the shift lever to P.*1

Depress the brake pedal.*1

Depress the clutch pedal.*2

Confirm that the key warning light is displayed, and then press the engine switch and check that the engine cranks.

*1: except Manual Transaxle

*2: for Manual Transaxle

- OK:

Engine cranks.

- Result:

Proceed to OK NG

OK

NG

Get into the vehicle while carrying an electrical key transmitter sub-assembly.

Move the shift lever to P.*

*: except Manual Transaxle

Press the engine switch with the brake pedal released and check that the security indicator light changes from blinking to off at the same time that the power source mode changes to on (ACC).

- HINT:

-

It is determined that the immobiliser function is operating correctly if the security indicator light changes from blinking to off at the same time that the power source mode changes to on (ACC).

- OK:

Security indicator light changes from blinking to off at the same time that the power source mode changes to on (ACC).

- Result:

Proceed to OK NG

OK

NG

Get into the vehicle while carrying the electrical key transmitter sub-assembly, move the shift lever to P*1, depress the brake pedal*1 or clutch pedal*2 and check that the combination meter indicator changes.

- HINT:

-

If the key warning light is displayed when the procedure above is performed, the P, N position detection signal*1 and stop light switch signal*1 or clutch start switch signal*2 can be considered to be normal.

*1: except Manual Transaxle

*2: for Manual Transaxle

- OK:

The key warning light is displayed.

- Result:

Result Proceed to OK A NG (except Manual Transaxle) B NG (for Manual Transaxle) C

A

B

C

Connect the GTS to the DLC3.

Turn the engine switch on (IG).

Turn the GTS on.

Enter the following menus: Body Electrical / Starting Control / Data List.

Get into the vehicle while carrying the electrical key transmitter sub-assembly, move the shift lever to P*1, press the engine switch while depressing the brake pedal*1 or clutch pedal*2 and confirm that the Data List item changes.

*1: except Manual Transaxle

*2: for Manual Transaxle

- Body Electrical > Starting Control > Data List

-

Tester Display Measurement Item Range Normal Condition Diagnostic Note Starter SW Starter operation request ON or OFF ON: Starter operation requested

OFF: Starter operation not requestedWhen malfunctioning, the engine will not crank.

- Body Electrical > Starting Control > Data List

-

Tester Display Starter SW - 50003 221 1

- OK:

The GTS display changes correctly in response to the vehicle condition.

- Result:

Proceed to OK NG

OK

NG

Click hereEngine / Hybrid System>2ZR-FE STARTING>RELAY>ON-VEHICLE INSPECTION

- Result:

Proceed to OK NG

OK

NG

Install the ST NO. 1 relay to the engine room relay block and junction block assembly.

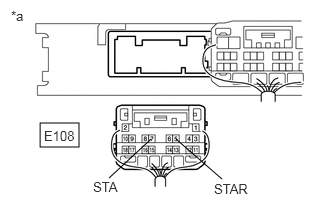

| *a | Rear view of wire harness connector

(to Certification ECU (Smart Key ECU Assembly)) |

Disconnect the E108 certification ECU (smart key ECU assembly) connector.

Move the shift lever to P or N.*1

Depress the clutch pedal.*2

Measure the resistance according to the value(s) in the table below.

*1: except Manual Transaxle

*2: for Manual Transaxle

- Standard Resistance:

Tester Connection Condition Specified Condition E108-5 (STAR) - Body ground 20°C (68°F) 98 to 146 Ω E108-7 (STA) - Body ground

- Result:

Proceed to OK NG

OK

NG

Remove the starter assembly.

Click hereEngine / Hybrid System>2ZR-FE STARTING>STARTER>REMOVAL

Inspect the starter assembly.

Click hereEngine / Hybrid System>2ZR-FE STARTING>STARTER>INSPECTION

- Result:

Proceed to OK NG

OK

NG

Remove the ST NO. 1 relay from the engine room relay block and junction block assembly.

Measure the voltage according to the value(s) in the table below.

- Standard Voltage:

Tester Connection Condition Specified Condition B5-1 - Body ground Always 11 to 14 V ST NO. 1 relay terminal 5 - Body ground

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection Condition Specified Condition ST NO. 1 relay terminal 3 - B9-1 Always Below 1 Ω ST NO. 1 relay terminal 3 or B9-1 - Body ground 10 kΩ or higher

- Result:

Proceed to OK NG

OK

NG

Connect the GTS to the DLC3.

Turn the engine switch on (IG).

Turn the GTS on.

Enter the following menus: Body Electrical / Power Source Control or Starting Control / Data List.

Read the Data List according to the display on the GTS.

- Body Electrical > Power Source Control > Data List

-

Tester Display Measurement Item Range Normal Condition Diagnostic Note Neutral SW/ Clutch SW Shift position (P and N) ON or OFF ON: Shift lever in P or N

OFF: Shift lever in any position other than P or N·Use this item to determine whether the park/neutral position switch assembly is malfunctioning.

·When the engine cannot be started due to a park/neutral position switch assembly malfunction, OFF is displayed.

- Body Electrical > Power Source Control > Data List

-

Tester Display Neutral SW/ Clutch SW - 50003 223 6

- Body Electrical > Starting Control > Data List

-

Tester Display Measurement Item Range Normal Condition Diagnostic Note Shift Position P or N Park/neutral position switch status ON or OFF ON: Shift lever in P or N

OFF: Shift lever not in P or NWhen malfunctioning, the engine will not crank.

- Body Electrical > Starting Control > Data List

-

Tester Display Shift Position P or N - 50003 221 2

- OK:

The GTS display changes correctly in response to the shift position.

- Result:

Proceed to OK NG

OK

NG

Read the Data List according to the display on the GTS.

- Body Electrical > Power Source Control > Data List

-

Tester Display Measurement Item Range Normal Condition Diagnostic Note Stop Light Switch1 State of brake pedal ON or OFF ON: Brake pedal depressed

OFF: Brake pedal released·Use this item to determine whether the stop light switch is malfunctioning.

·The engine cannot be started when this item is OFF.

·When this item is malfunctioning, the engine can be started by pressing and holding the engine switch for a certain period of time.

- Body Electrical > Power Source Control > Data List

-

Tester Display Stop Light Switch1 - 50003 223 3

- OK:

The GTS display changes correctly in response to the brake operation.

- Result:

Proceed to OK NG

OK

NG

Remove the stop light switch assembly.

Click hereVehicle Exterior>LIGHTING (EXT)>STOP LIGHT SWITCH>REMOVAL

Inspect the stop light switch assembly.

Click hereVehicle Exterior>LIGHTING (EXT)>STOP LIGHT SWITCH>ON-VEHICLE INSPECTION

- Result:

Proceed to OK NG

OK

NG

- Result:

Proceed to OK NG

OK

NG

Remove the park/neutral position switch assembly.

Click hereDrivetrain>K313 CVT>PARK / NEUTRAL POSITION SWITCH>REMOVAL

Inspect the park/neutral position switch assembly.

Click hereDrivetrain>K313 CVT>PARK / NEUTRAL POSITION SWITCH>INSPECTION

- Result:

Proceed to OK NG

OK

NG

Disconnect the E108 certification ECU (smart key ECU assembly) connector.

Disconnect the B14 park/neutral position switch assembly connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection Condition Specified Condition E108-5 (STAR) - B14-4 (B) Always Below 1 Ω E108-5 (STAR) or B14-4 (B) - Body ground Always 10 kΩ or higher

Reconnect the B14 park/neutral position switch assembly connector.

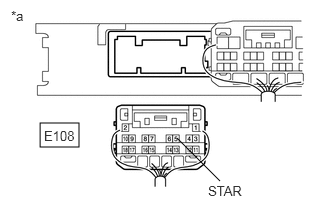

| *a | Rear view of wire harness connector

(to Certification ECU (Smart Key ECU Assembly) |

Measure the voltage according to the value(s) in the table below.

- Standard Voltage:

Tester Connection Condition Specified Condition E108-5 (STAR) - Body ground Engine switch pressed and held with brake pedal depressed (starter on) → Engine switch released after approximately 1 second elapses (starter off) 9.5 V or higher* → 1 V or less

- HINT:

-

*: When the engine is cranking, the battery voltage may momentarily drop to approximately 6 V.

- Result:

Proceed to OK NG

OK

NG

Connect the GTS to the DLC3.

Turn the engine switch on (IG).

Turn the GTS on.

Enter the following menus: Body Electrical / Power Source Control / Data List.

Read the Data List according to the display on the GTS.

- Body Electrical > Power Source Control > Data List

-

Tester Display Measurement Item Range Normal Condition Diagnostic Note Neutral SW/ Clutch SW State of clutch pedal ON or OFF ON: Clutch pedal depressed

OFF: Clutch pedal released·Use this item to help determine if the clutch start switch assembly is malfunctioning.

·The engine cannot be started when this item is OFF.

- Body Electrical > Power Source Control > Data List

-

Tester Display Neutral SW/ Clutch SW - 50003 223 6

- OK:

The GTS display changes correctly in response to the clutch pedal operation.

- Result:

Proceed to OK NG

OK

NG

Remove the clutch start switch assembly.

Inspect the clutch start switch assembly.

- Result:

Proceed to OK NG

OK

NG

Disconnect the E108 certification ECU (smart key ECU assembly) connector.

Disconnect the A57 clutch start switch assembly connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection Condition Specified Condition E108-5 (STAR) - A57-2 Always Below 1 Ω E108-5 (STAR) or A57-2 - Body ground Always 10 kΩ or higher

Reconnect the A57 the clutch start switch assembly connector.

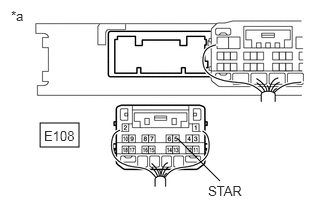

| *a | Rear view of wire harness connector

(to Certification ECU (Smart Key ECU Assembly)) |

Measure the voltage according to the value(s) in the table below.

- Standard Voltage:

Tester Connection Condition Specified Condition E108-5 (STAR) - Body ground Engine switch pressed and held with clutch pedal depressed (starter on) → Engine switch released after approximately 1 second elapses (starter off) 9.5 V or higher* → 1 V or less

- HINT:

-

*: When the engine is cranking, the battery voltage may momentarily drop to approximately 6 V.

- Result:

Proceed to OK NG

OK

NG

Connect the GTS to the DLC3.

Turn the engine switch on (IG).

Turn the GTS on.

Enter the following menus: Body Electrical / Entry&Start / Data List.

Read the Data List according to the display on the GTS.

- Body Electrical > Entry&Start > Data List

-

Tester Display Measurement Item Range Normal Condition Diagnostic Note S Code Check Verification result between certification ECU (smart key ECU assembly) and ID code box (immobiliser code ECU) OK or NG OK: Verification result normal

NG: Verification result abnormalWhen NG is displayed:

·The ID code for the certification ECU (smart key ECU assembly) or ID code box (immobiliser code ECU) is not registered or the certification ECU (smart key ECU assembly) or ID code box (immobiliser code ECU) is malfunctioning.

·The steering cannot be locked.

·The steering cannot be unlocked (the engine cannot be started).

- Body Electrical > Entry&Start > Data List

-

Tester Display S Code Check - 50003 125 65

- HINT:

-

Reasons for verification failure:

- ·

The certification ECU (smart key ECU assembly) or ID code box (immobiliser code ECU) is malfunctioning.

·There is a problem with the communication between ECUs.

·An ECU has been replaced, but is not registered.

·An ECU has been replaced with an ECU which has a code already stored in it.

- OK:

OK (S code verification result normal) appears on the screen.

- Result:

Proceed to OK NG

OK

NG

Check that the steering unlocks when the engine switch is turned on (ACC).

- OK:

The steering unlocks.

- Result:

Proceed to OK NG

OK

NG

Read the Data List according to the display on the GTS.

- Body Electrical > Entry&Start > Data List

-

Tester Display Measurement Item Range Normal Condition Diagnostic Note Immobiliser Immobiliser system determined by certification ECU (smart key ECU assembly) Set or Unset Set: Immobiliser set (engine start prohibited) (engine switch off)

Unset: Immobiliser unset (engine start permitted) (engine switch on (ACC) or on (IG))The engine cannot be started when Set is displayed.

- HINT:

- ·

The security indicator light blinks when Set is displayed.

·The security indicator light is linked with set/unset of the immobiliser and not linked with steering lock/unlock.

- Body Electrical > Entry&Start > Data List

-

Tester Display Immobiliser - 50003 125 34

- OK:

The GTS display changes correctly in response to the immobiliser condition.

- Result:

Proceed to OK NG

OK

NG

Enter the following menus: Body Electrical / Power Source Control / Data List.

Read the Data List according to the display on the GTS.

- Body Electrical > Power Source Control > Data List

-

Tester Display Measurement Item Range Normal Condition Diagnostic Note Starter Request Signal Engine start request signal status ON or OFF except Manual Transaxle:ON: With the shift lever in P and brake pedal depressed, the engine switch is pressed and held

OFF: After approx. 1 sec. has elapsed, the engine switch is released

for Manual Transaxle:ON: With the clutch pedal depressed, the engine switch is pressed and held

OFF: After approx. 1 sec. has elapsed, the engine switch is released

·When the engine cannot be started due to a start request signal malfunction, OFF is displayed.

·When the engine switch is pressed, the duration of time that ON is displayed will be extremely short. As such, the engine switch needs to be pressed and held for a certain amount of time.

- Body Electrical > Power Source Control > Data List

-

Tester Display Starter Request Signal - 50003 223 12

- NOTICE:

- ·

Check that the key warning light is displayed on the multi-information display in the combination meter assembly, and then press the engine switch.

·Check that the key warning light is displayed on the multi-information display in the combination meter assembly, and then press the engine switch.

- OK:

The GTS display changes correctly in response to the operation of the engine switch.

- Result:

Proceed to OK NG

OK

Click hereGeneral>INTRODUCTION>HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMS>HOW TO PROCEED WITH TROUBLESHOOTING

NG

Enter the following menus: Body Electrical / Power Source Control / Data List.

Read the Data List according to the display on the GTS.

- Body Electrical > Power Source Control > Data List

-

Tester Display Measurement Item Range Normal Condition Diagnostic Note Steering Unlock Switch State of steering unlock sensor signal output from steering lock actuator assembly ON or OFF ON: Steering unlocked

OFF: Steering locked·When the shift lever is in P* and the engine switch is off, if any door is opened or closed, the steering is locked.

·When the electrical key transmitter sub-assembly is inside the vehicle and the engine switch is turned on (ACC) or on (IG), the steering unlocks.

·The engine cannot be started when the steering unlock signal is off.

- Body Electrical > Power Source Control > Data List

-

Tester Display Steering Unlock Switch - 50003 223 2

*: except Manual Transaxle

- OK:

The GTS display changes correctly in response to the steering condition.

- Result:

Proceed to OK NG

OK

Click hereSteering>STEERING COLUMN>STEERING LOCK SYSTEM>Unable to Unlock Steering Wheel (Engine cannot Start)

NG

Enter the following menus: Body Electrical / Entry&Start / Data List.

Read the Data List according to the display on the GTS.

- Body Electrical > Entry&Start > Data List

-

Tester Display Measurement Item Range Normal Condition Diagnostic Note L Code Check Verification result between ID code box (immobiliser code ECU) and steering lock ECU (steering lock actuator assembly) OK or NG OK: Verification result normal

NG: Verification result abnormalWhen NG is displayed:

·The ID code for the ID code box (immobiliser code ECU) or steering lock ECU (steering lock actuator assembly) is not registered or the ID code box (immobiliser code ECU) or steering lock ECU (steering lock actuator assembly) is malfunctioning.

·The steering cannot be locked.

·The steering cannot be unlocked (the engine cannot be started).

- Body Electrical > Entry&Start > Data List

-

Tester Display L Code Check - 50003 125 66

- HINT:

-

Reasons for verification failure:

- ·

The steering lock ECU (steering lock actuator assembly) or ID code box (immobiliser code ECU) is malfunctioning.

·There is a problem with the communication between ECUs.

·An ECU has been replaced, but is not registered.

·An ECU has been replaced with an ECU which has a code already stored in it.

- OK:

OK (L code verification result normal) appears on the screen.

- Result:

Proceed to OK NG

OK

NG

Replace the certification ECU (smart key ECU assembly) with a new one.

Perform the registration procedures.

- HINT:

-

Refer to Service Bulletin.

Use the Data List to check if S code certification is functioning properly again.

- Body Electrical > Entry&Start > Data List

-

Tester Display Measurement Item Range Normal Condition Diagnostic Note S Code Check Verification result between certification ECU (smart key ECU assembly) and ID code box (immobiliser code ECU) OK or NG OK: Verification result normal

NG: Verification result abnormalWhen NG is displayed:

·The ID code for the certification ECU (smart key ECU assembly) or ID code box (immobiliser code ECU) is not registered or the certification ECU (smart key ECU assembly) or ID code box (immobiliser code ECU) is malfunctioning.

·The steering cannot be locked.

·The steering cannot be unlocked (the engine cannot be started).

- Body Electrical > Entry&Start > Data List

-

Tester Display S Code Check - 50003 125 65

- OK:

OK (S code certification result normal) appears on the screen.

- Result:

Proceed to OK NG

OK

NG

Replace the steering lock ECU (steering lock actuator assembly) with a new one.

Click hereSteering>STEERING COLUMN>STEERING COLUMN ASSEMBLY>DISASSEMBLY

Perform the registration procedures.

- HINT:

-

Refer to Service Bulletin.

Use the Data List to check if L code verification is functioning properly again

- Body Electrical > Entry&Start > Data List

-

Tester Display Measurement Item Range Normal Condition Diagnostic Note L Code Check Verification result between ID code box (immobiliser code ECU) and steering lock ECU (steering lock actuator assembly) OK or NG OK: Verification result normal

NG: Verification result abnormalWhen NG is displayed:

·The ID code for the ID code box (immobiliser code ECU) or steering lock ECU (steering lock actuator assembly) is not registered or the ID code box (immobiliser code ECU) or steering lock ECU (steering lock actuator assembly) is malfunctioning.

·The steering cannot be locked.

·The steering cannot be unlocked (the engine cannot be started).

- Body Electrical > Entry&Start > Data List

-

Tester Display L Code Check - 50003 125 66

- OK:

OK (L code verification result normal) appears on the screen.

- Result:

Proceed to OK NG

OK

NG

Replace the ID code box (immobiliser code ECU) with a new one.

- HINT:

-

Refer to Service Bulletin.

Perform the registration procedures.

- HINT:

-

Refer to Service Bulletin.

Use the Data List to check if S code verification is functioning properly again.

- Body Electrical > Entry&Start > Data List

-

Tester Display Measurement Item Range Normal Condition Diagnostic Note S Code Check Verification result between certification ECU (smart key ECU assembly) and ID code box (immobiliser code ECU) OK or NG OK: Verification result normal

NG: Verification result abnormalWhen NG is displayed:

·The ID code for the certification ECU (smart key ECU assembly) or ID code box (immobiliser code ECU) is not registered or the certification ECU (smart key ECU assembly) or ID code box (immobiliser code ECU) is malfunctioning.

·The steering cannot be locked.

·The steering cannot be unlocked (the engine cannot be started).

- Body Electrical > Entry&Start > Data List

-

Tester Display S Code Check - 50003 125 65

- OK:

OK (S code verification result normal) appears on the screen.

- Result:

Proceed to NEXT

NEXT