2ZR-FE ENGINE MECHANICAL CYLINDER BLOCK DISASSEMBLY

PROCEDURE

12211

1.REMOVE NO. 1 VENTILATION CASE

12211

1.REMOVE NO. 1 VENTILATION CASE

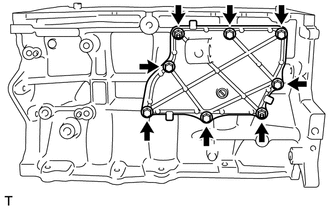

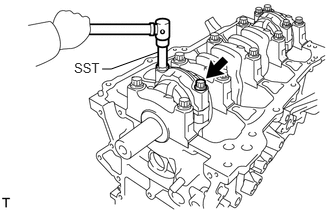

Remove the 6 bolts and 2 nuts.

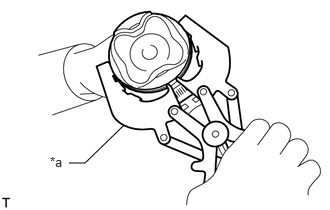

| *a | Protective Tape |

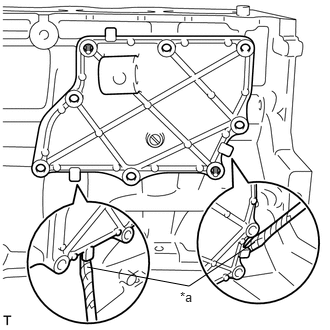

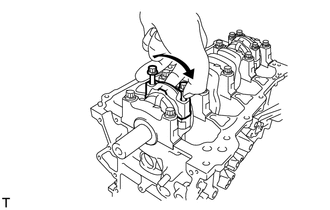

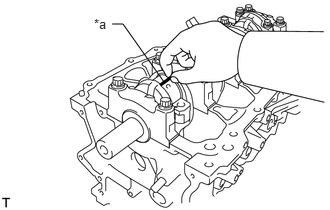

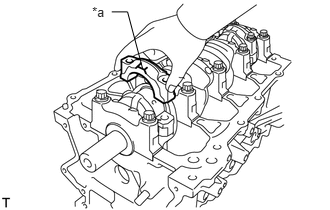

Remove the No. 1 ventilation case by prying between the No. 1 ventilation case and cylinder block sub-assembly with a screwdriver as shown in the illustration.

- NOTICE:

-

Be careful not to damage the contact surfaces of the cylinder block sub-assembly and No. 1 ventilation case.

- HINT:

-

Tape the screwdriver tip before use.

2.INSPECT CONNECTING ROD THRUST CLEARANCE

2.INSPECT CONNECTING ROD THRUST CLEARANCE

Using a dial indicator, measure the thrust clearance while moving the connecting rod cap back and forth.

- Standard Thrust Clearance:

0.160 to 0.342 mm (0.00630 to 0.0135 in.)

- Maximum Thrust Clearance:

0.342 mm (0.0135 in.)

If the thrust clearance is greater than the maximum, replace the connecting rod sub-assembly as necessary. If necessary, replace the crankshaft.

3.INSPECT CONNECTING ROD OIL CLEARANCE

3.INSPECT CONNECTING ROD OIL CLEARANCE

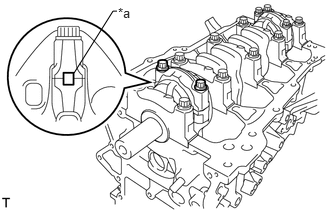

| *a | Matchmark |

Check that the matchmarks on the connecting rod and connecting rod cap are aligned to ensure correct reassembly.

- HINT:

-

The matchmarks on the connecting rods and connecting rod caps are provided to ensure correct reassembly.

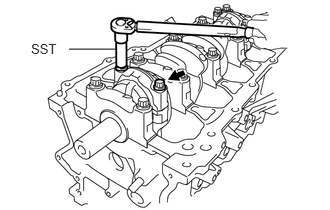

Using SST, uniformly loosen and remove the 2 connecting rod bolts.

- SST

- 09205-16011

Using the 2 removed connecting rod bolts, remove the connecting rod cap and connecting rod bearing by wiggling the connecting rod cap back and forth.

- HINT:

-

Keep the connecting rod bearing inserted in the connecting rod cap.

Clean the crank pin and connecting rod bearing.

Check the crank pin and connecting rod bearing for pitting and scratches.

If the crank pin or connecting rod bearing is damaged, replace the connecting rod bearings. If necessary, replace the crankshaft.

| *a | Plastigage |

Lay a strip of Plastigage on the crank pin.

| *a | Front Mark |

Check that the front mark of the connecting rod cap is facing forward and install the connecting rod cap.

Apply a light coat of engine oil to the threads and under the heads of the connecting rod bolts.

Install the connecting rod bolts.

- NOTICE:

-

The connecting rod bolts are tightened in 2 progressive steps.

Step 1:

Using SST, alternately tighten the connecting rod bolts in several steps.

- SST

- 09205-16011

- Torque:

- 20 N*m (204 kgf*cm, 15 ft.*lbf)

- NOTICE:

-

Do not turn the crankshaft.

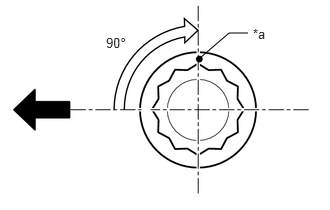

| *a | Paint Mark |

|

Engine Front |

Step 2:

Mark the front of the connecting rod bolts with paint.

Further tighten the connecting rod bolts by 90° as shown in the illustration.

- NOTICE:

-

Do not turn the crankshaft.

Remove the 2 connecting rod bolts and connecting rod cap.

- HINT:

-

Keep the lower bearing inserted in the connecting rod cap.

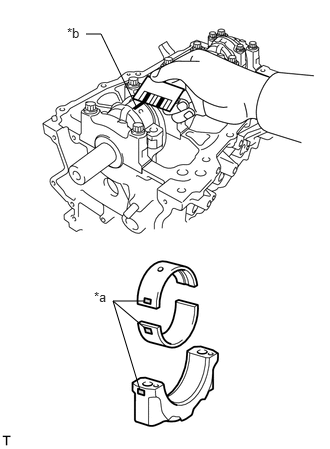

| *a | Mark 1, 2 or 3 |

| *b | Plastigage |

Measure the Plastigage at its widest point.

- Standard Oil Clearance:

0.014 to 0.038 mm (0.000551 to 0.00150 in.)

- Maximum Oil Clearance:

0.070 mm (0.00276 in.)

If the oil clearance is greater than the maximum, replace the connecting rod bearings. If necessary, replace the crankshaft.

- NOTICE:

-

Remove the Plastigage completely after the measurement.

- HINT:

-

If replacing a connecting rod bearing, replace it with one that has the same number as its respective connecting rod cap. Each connecting rod bearing standard thickness is indicated by mark 1, 2 or 3 on its surface.

- Standard Connecting Rod Large End Bore Diameter:

Mark Specified Condition 1 47.000 to 47.008 mm (1.85039 to 1.85070 in.) 2 47.009 to 47.016 mm (1.85074 to 1.85102 in.) 3 47.017 to 47.024 mm (1.85106 to 1.85133 in.)

- Standard Connecting Rod Bearing Thickness:

Mark Specified Condition 1 1.489 to 1.493 mm (0.058622 to 0.058779 in.) 2 1.494 to 1.497 mm (0.058819 to 0.058937 in.) 3 1.498 to 1.501 mm (0.058976 to 0.059094 in.)

- Standard Crank Pin Diameter:

43.992 to 44.000 mm (1.7320 to 1.7323 in.)

Perform the inspection above for each cylinder.

4.REMOVE PISTON SUB-ASSEMBLY WITH CONNECTING ROD

4.REMOVE PISTON SUB-ASSEMBLY WITH CONNECTING ROD

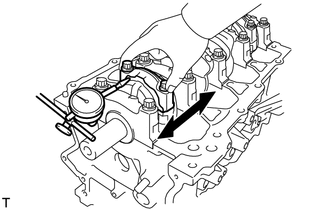

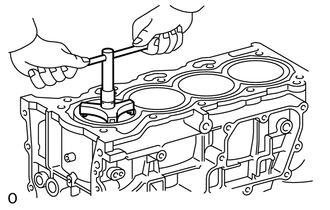

Using a ridge reamer, scrape off any carbon on the top of the cylinder.

Push the piston, connecting rod and connecting rod bearing through the top of the cylinder block sub-assembly.

- HINT:

- ·

Keep the connecting rod bearings, connecting rod and connecting rod cap together.

·Be sure to arrange the removed piston and connecting rod in such a way that they can be reinstalled exactly as before.

13041

5.REMOVE CONNECTING ROD BEARING

13041

5.REMOVE CONNECTING ROD BEARING

Remove the connecting rod bearings.

- HINT:

-

Arrange the removed parts in the correct order.

13011

6.REMOVE PISTON RING SET

13011

6.REMOVE PISTON RING SET

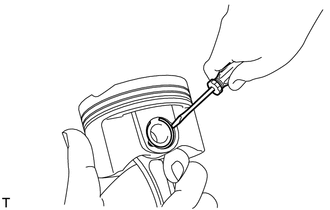

| *a | Piston Ring Expander |

Using a piston ring expander, remove the No. 1 compression ring and No. 2 compression ring.

for 2-piece Type:

Remove the oil ring and oil ring expander by hand.

- HINT:

-

Arrange the removed parts in the correct order.

for 3-piece Type:

Remove the oil ring expander, upper side rail and lower side rail by hand.

- HINT:

-

Arrange the removed parts in the correct order.

13101

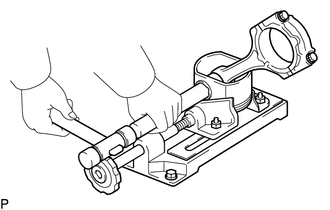

7.REMOVE PISTON

13101

7.REMOVE PISTON

Using a screwdriver, pry out the 2 piston pin hole snap rings.

Gradually heat each piston to approximately 80 to 90°C (176 to 194°F).

Using a plastic hammer and brass bar, lightly tap out the piston pin and remove the connecting rod.

- HINT:

- ·

The piston and piston pin are a matched set.

·Arrange the pistons, piston pins, piston rings, connecting rods and connecting rod bearings in the correct order.

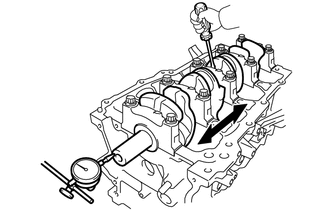

8.INSPECT CRANKSHAFT THRUST CLEARANCE

8.INSPECT CRANKSHAFT THRUST CLEARANCE

Using a dial indicator, measure the crankshaft thrust clearance while prying the crankshaft back and forth with a screwdriver.

- Standard Thrust Clearance:

0.04 to 0.14 mm (0.00157 to 0.00551 in.)

- Maximum Thrust Clearance:

0.18 mm (0.00709 in.)

If the crankshaft thrust clearance is more than the maximum, replace the upper crankshaft thrust washers as a set. If necessary, replace the crankshaft.

- HINT:

-

The upper crankshaft thrust washer thickness is 2.43 to 2.48 mm (0.0957 to 0.0976 in.).

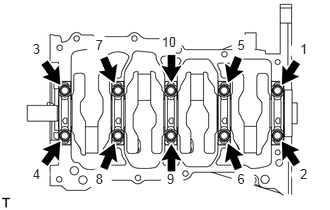

13411

9.REMOVE CRANKSHAFT

13411

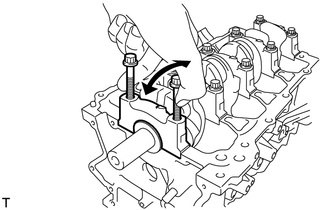

9.REMOVE CRANKSHAFT

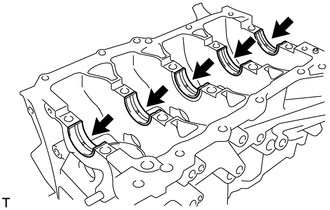

Uniformly loosen and remove the 10 crankshaft bearing cap set bolts in the order shown in the illustration.

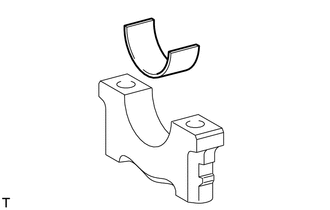

Using the 2 removed crankshaft bearing cap set bolts, remove the 5 crankshaft bearing caps and 5 crankshaft bearings.

- NOTICE:

-

Insert the crankshaft bearing cap set bolts into the crankshaft bearing caps in turn. Ease the crankshaft bearing cap out by gently pulling up while wiggling it back and forth as shown in the illustration. Do not damage the contact surfaces of the crankshaft bearing cap and cylinder block sub-assembly.

- HINT:

- ·

Keep the lower crankshaft bearing and crankshaft bearing cap together as a set.

·Arrange the crankshaft bearing caps in the correct order.

Lift out the crankshaft from the cylinder block sub-assembly.

Check each crankshaft journal and crankshaft bearing for pitting and scratches.

If the journal or crankshaft bearing is damaged, replace the crankshaft bearings. If necessary, replace the crankshaft.

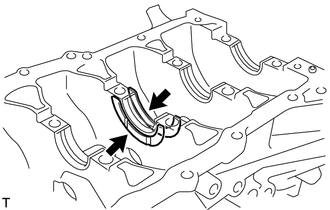

11791

10.REMOVE UPPER CRANKSHAFT THRUST WASHER

11791

10.REMOVE UPPER CRANKSHAFT THRUST WASHER

Remove the 2 upper crankshaft thrust washers from the No. 3 journal position of the cylinder block sub-assembly.

11711

11.REMOVE CRANKSHAFT BEARING

11711

11.REMOVE CRANKSHAFT BEARING

Remove the 5 upper crankshaft bearings from the cylinder block sub-assembly.

- HINT:

-

Arrange the removed parts in the correct order.

Remove the 5 lower crankshaft bearings from the 5 crankshaft bearing caps.

- HINT:

-

Arrange the removed parts in the correct order.

15708

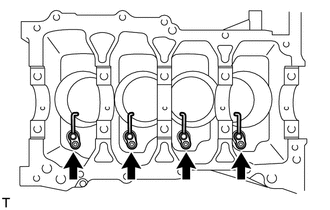

12.REMOVE NO. 1 OIL NOZZLE SUB-ASSEMBLY

15708

12.REMOVE NO. 1 OIL NOZZLE SUB-ASSEMBLY

Using a 5 mm hexagon socket wrench, remove the 4 bolts and 4 No. 1 oil nozzle sub-assemblies.

11401

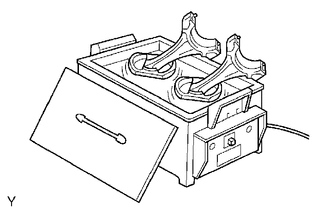

13.CLEAN CYLINDER BLOCK SUB-ASSEMBLY

11401

13.CLEAN CYLINDER BLOCK SUB-ASSEMBLY

- NOTICE:

-

If the cylinder block sub-assembly is washed at high temperatures, the cylinder liner will stick out beyond the cylinder block sub-assembly. Always wash the cylinder block sub-assembly at a temperature of 45°C (113°F) or less.